NU - AutoAquaponics:

Fall 2023 Update

NU - AutoAquaponics:

Fall 2023 Update

AutoAquaponics Progress From Fall of 2023

AutoAquaponics ended the year strong; we made meaningful progress towards a more efficient system, and we have much to look forward to in the coming year. To advance our goals, our team received a McCormick Student Advisory Board grant, and we are forever grateful for their support. We also saw new members join our team, Lily Li, Samreen Ibrahim, Adam Elsharkawi, and Lev Rosenburg;. Welcome to the fish bowl y’all!

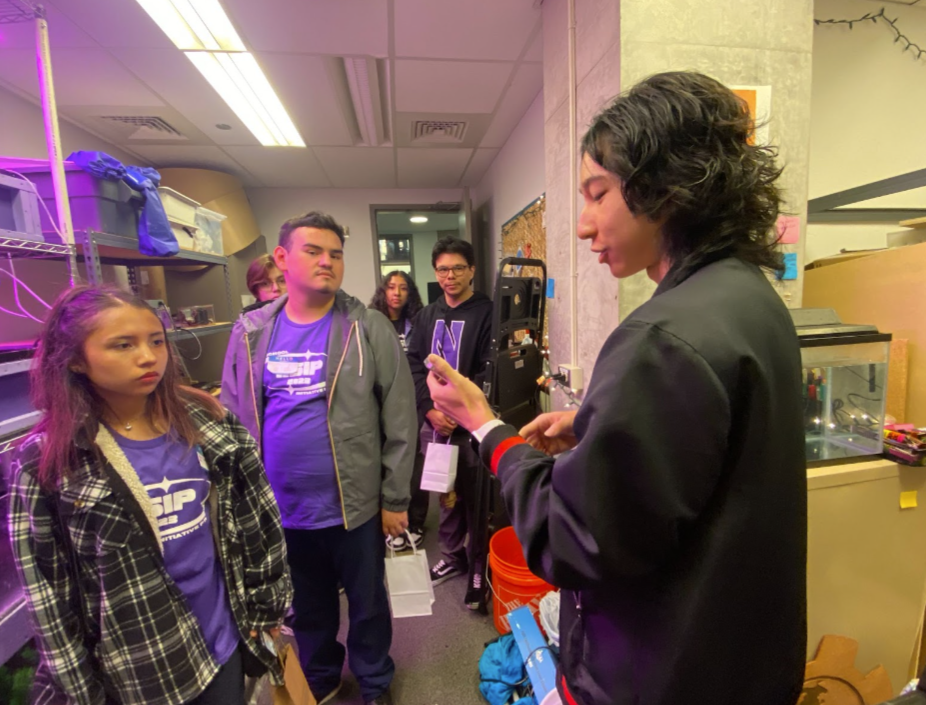

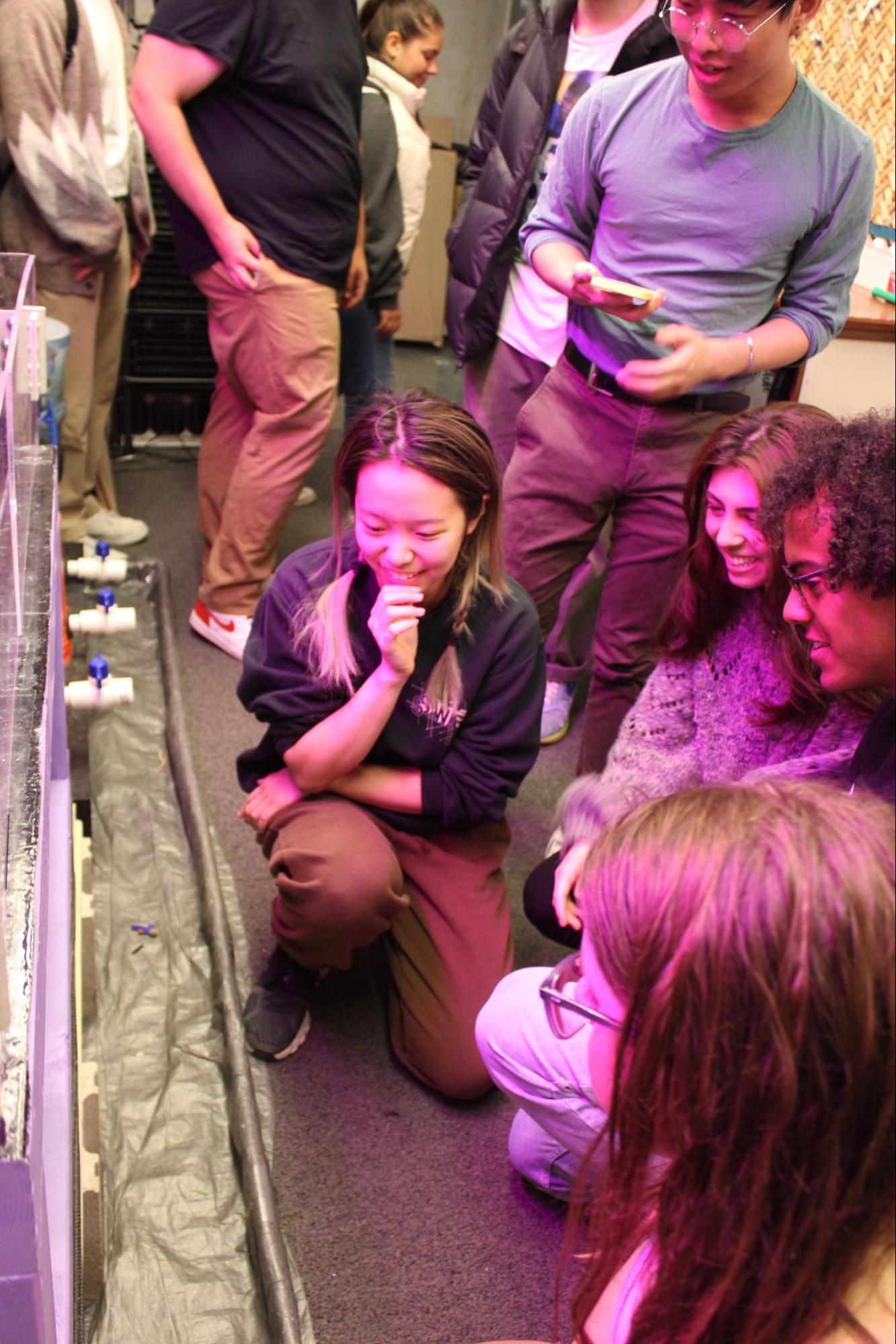

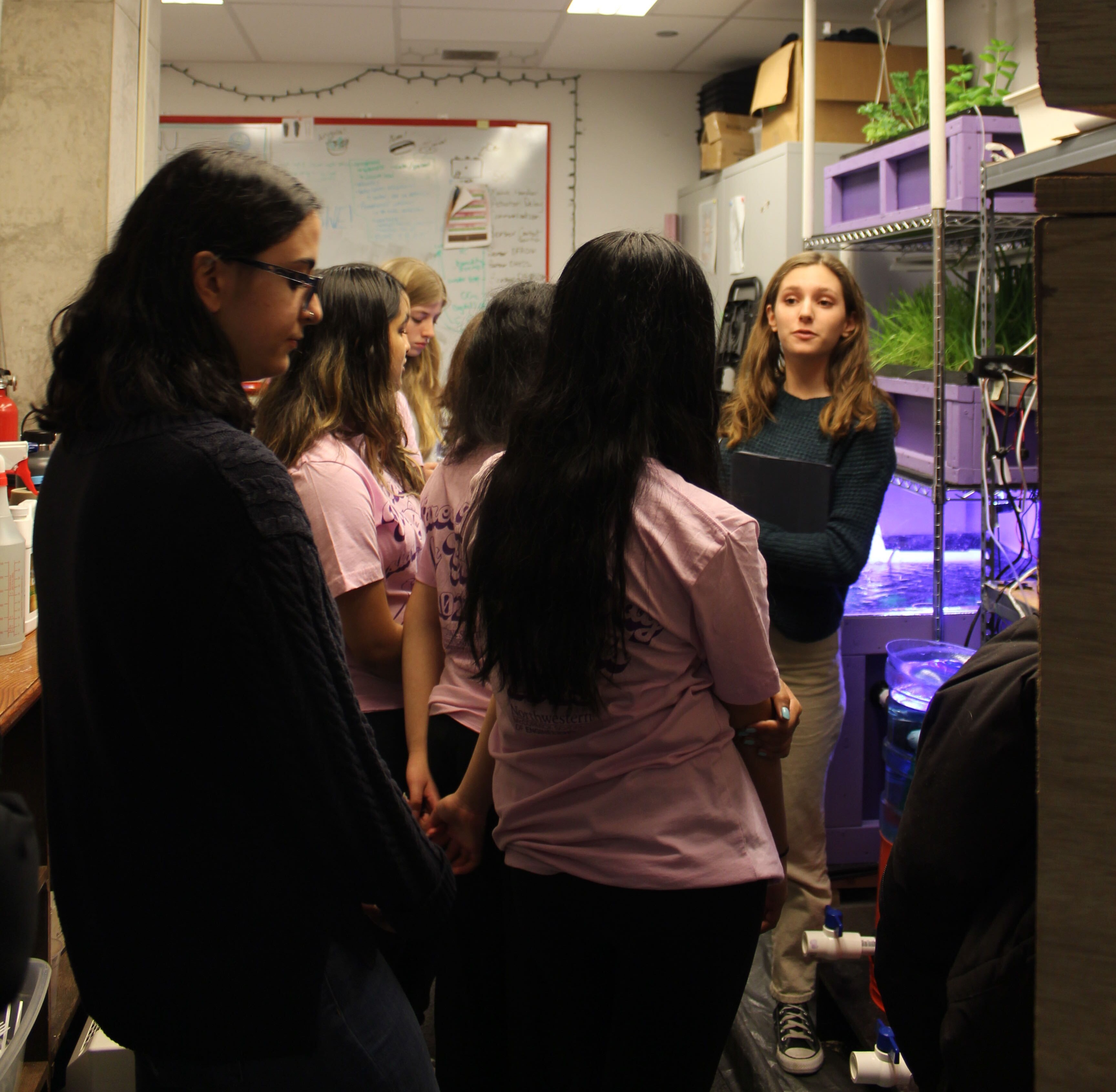

To continue engagement with the Chicagoland community, our team gave a tour of the system to high schoolers participating in NU Society of Hispanic Professional Engineers’ High School Initiative Program! These high school students, primarily from minority and low-income backgrounds, come to Northwestern to discover what higher education in STEM has to offer. This includes our magnificent system! Special thanks to NU Society of Hispanic Professional Engineers for presenting this opportunity and to our lovely volunteers, Andre and Aliza, who came to help with the tour!

Plumbing¶

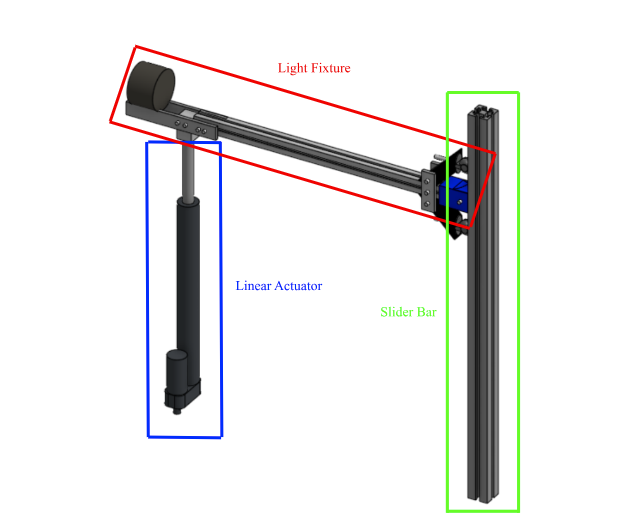

While we waited for membrane filter funding, our team got to work on some other improvements and exciting projects. The final design for our UV light filter was designed and installed in the system. Now, we should not have algae overgrowth.

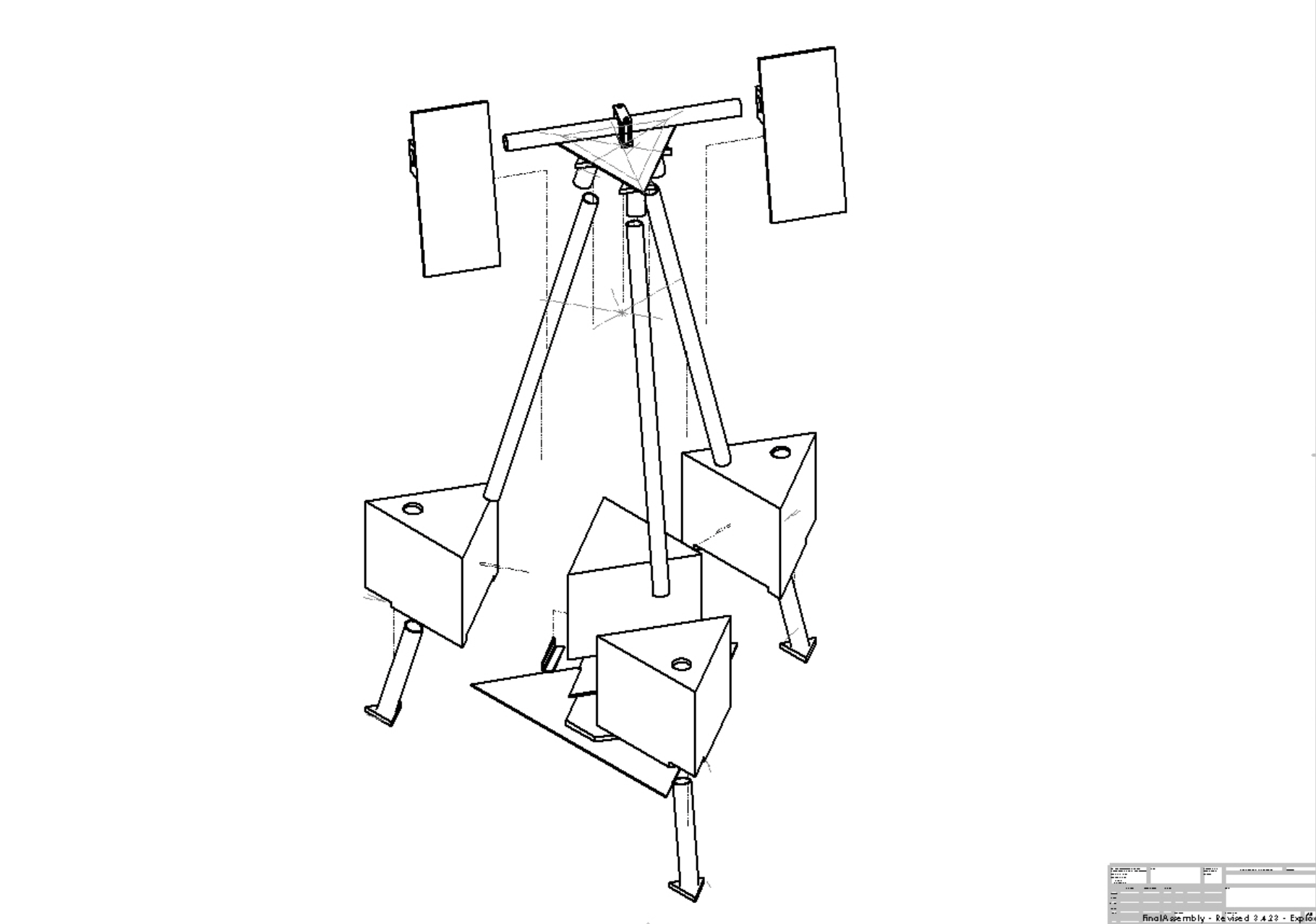

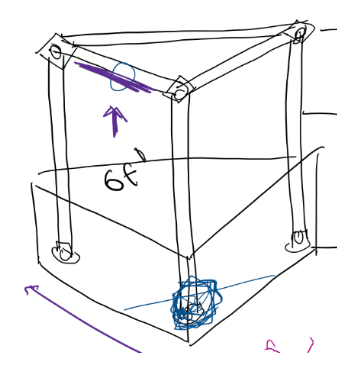

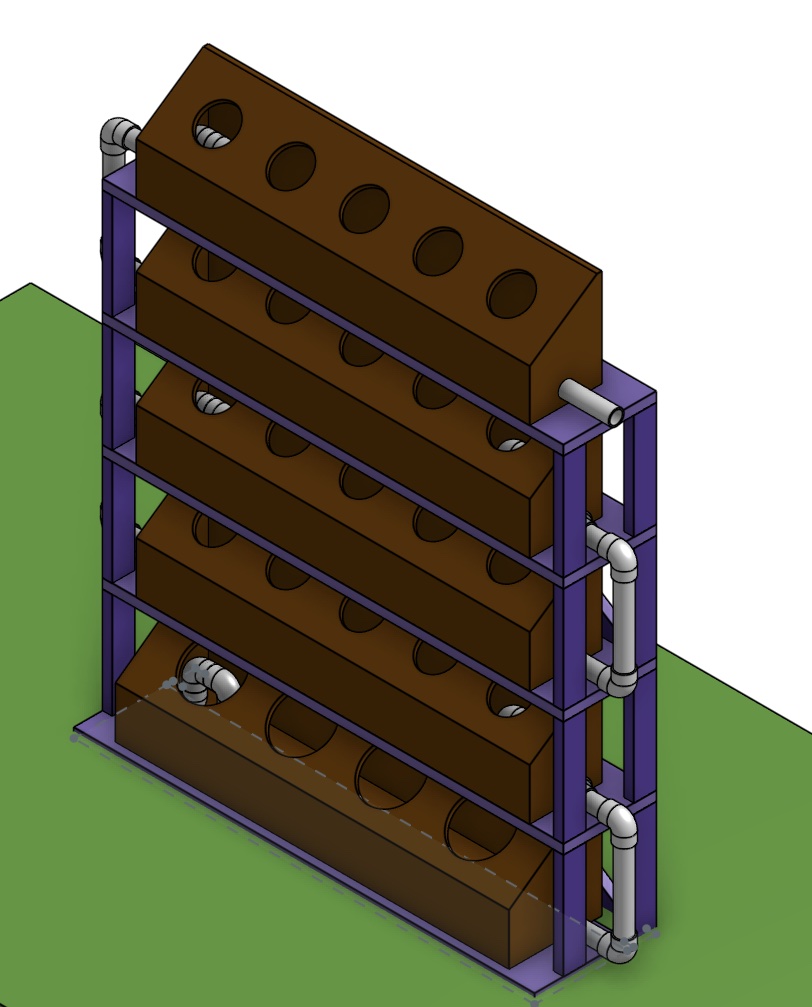

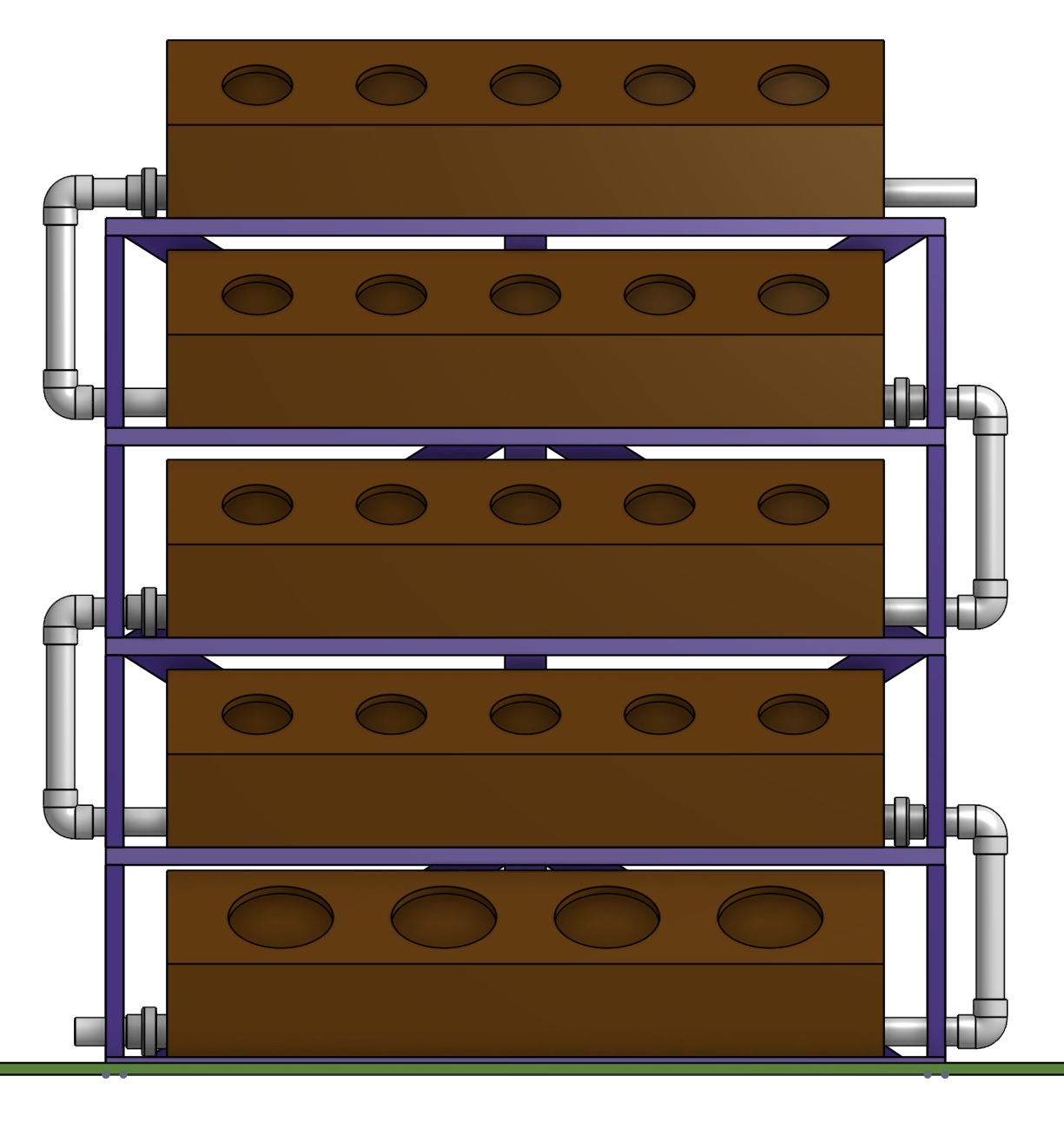

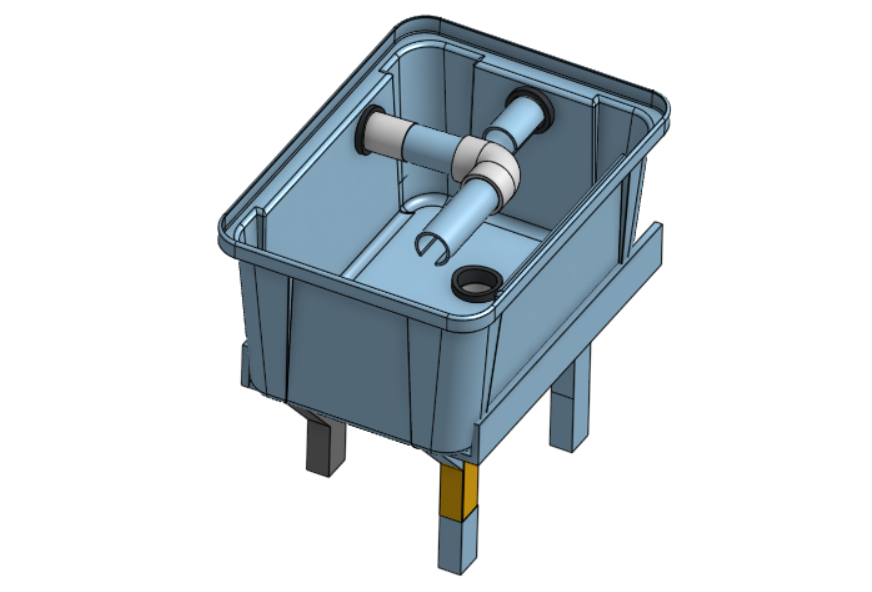

Our members played around with the idea of a black soldier fly farm to provide a continuous source of food for the fish tank. The idea is to have flies lay their eggs in a container with compost that traps the fly larva and leverages inherent biological processes of the soldier fly life-cycle to automatically collect larvae once they mature. The larva will then be processed and fed to the fish.

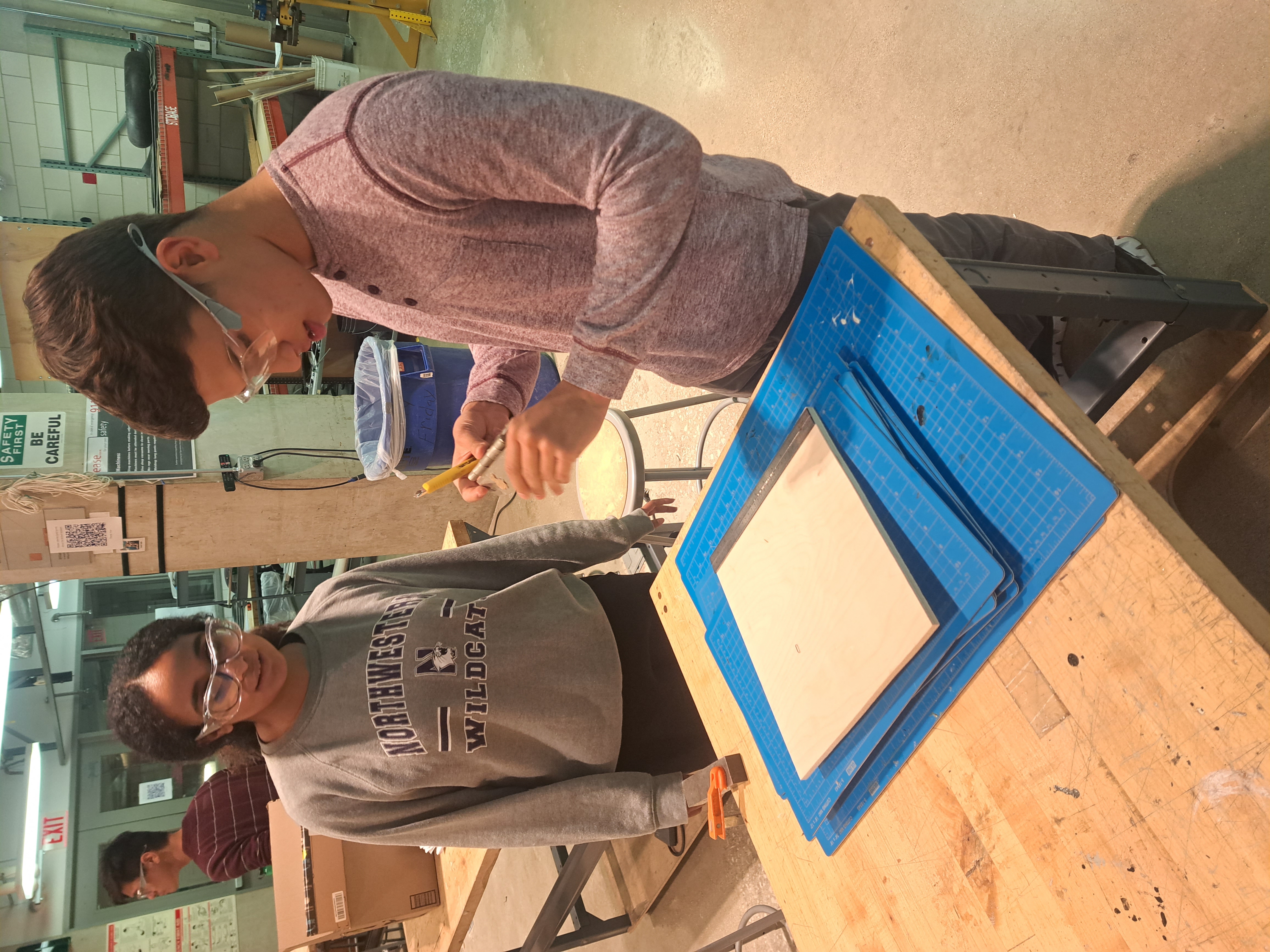

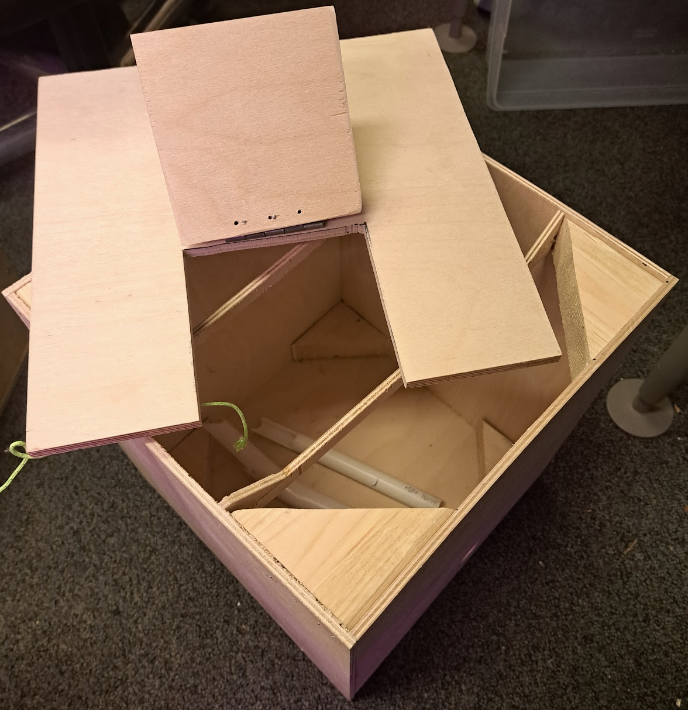

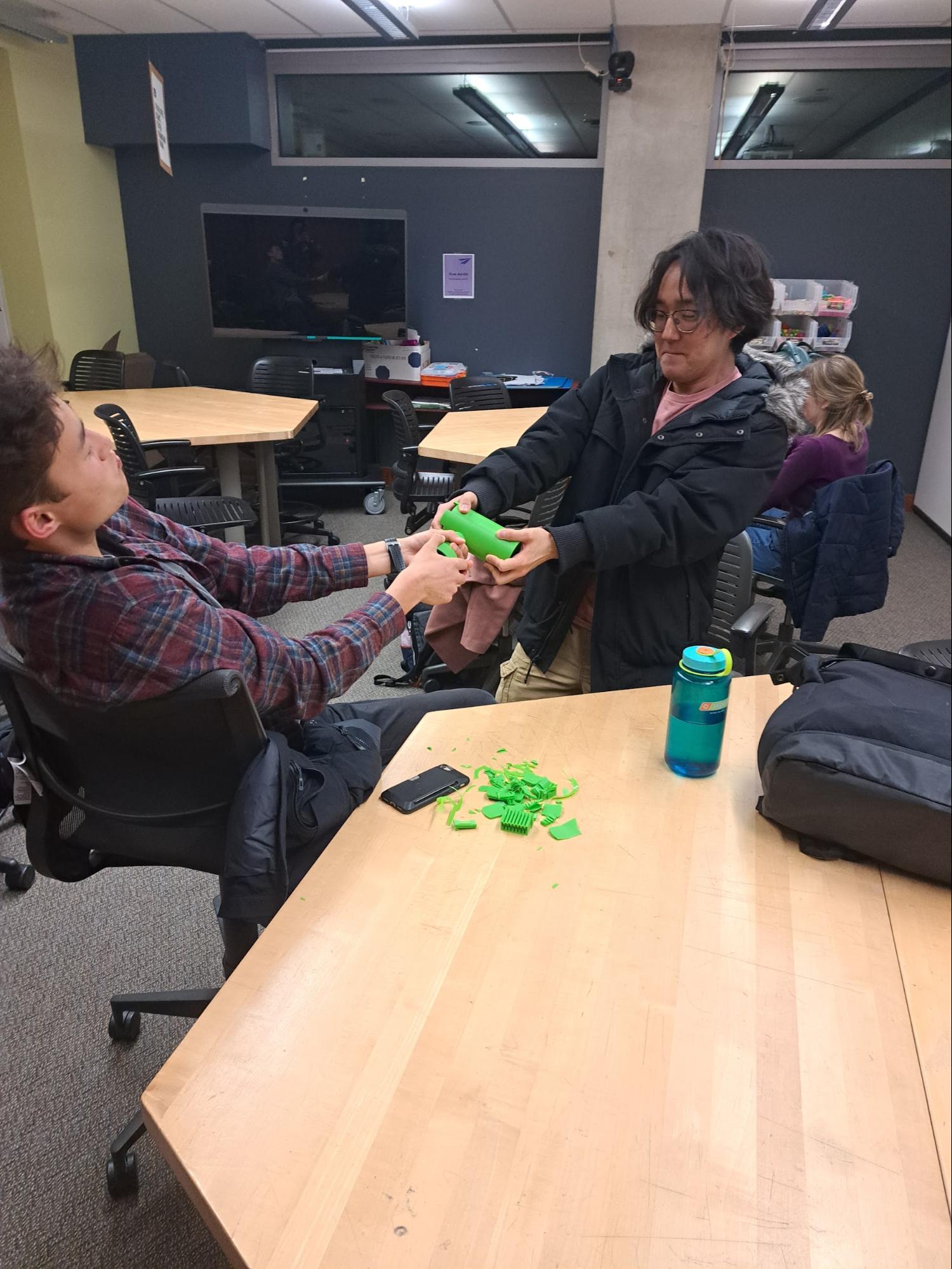

Construction of the first few prototypes:

Unfortunately, Evanston got too cold for flies to be out, so our experiments could no longer continue. Check back in the spring when the weather is warm!

As a supplement to the black soldier fly farm, the plumbing team worked on a compost reactor to supply the black soldier farm with a steady stream of new food when the farm is up.

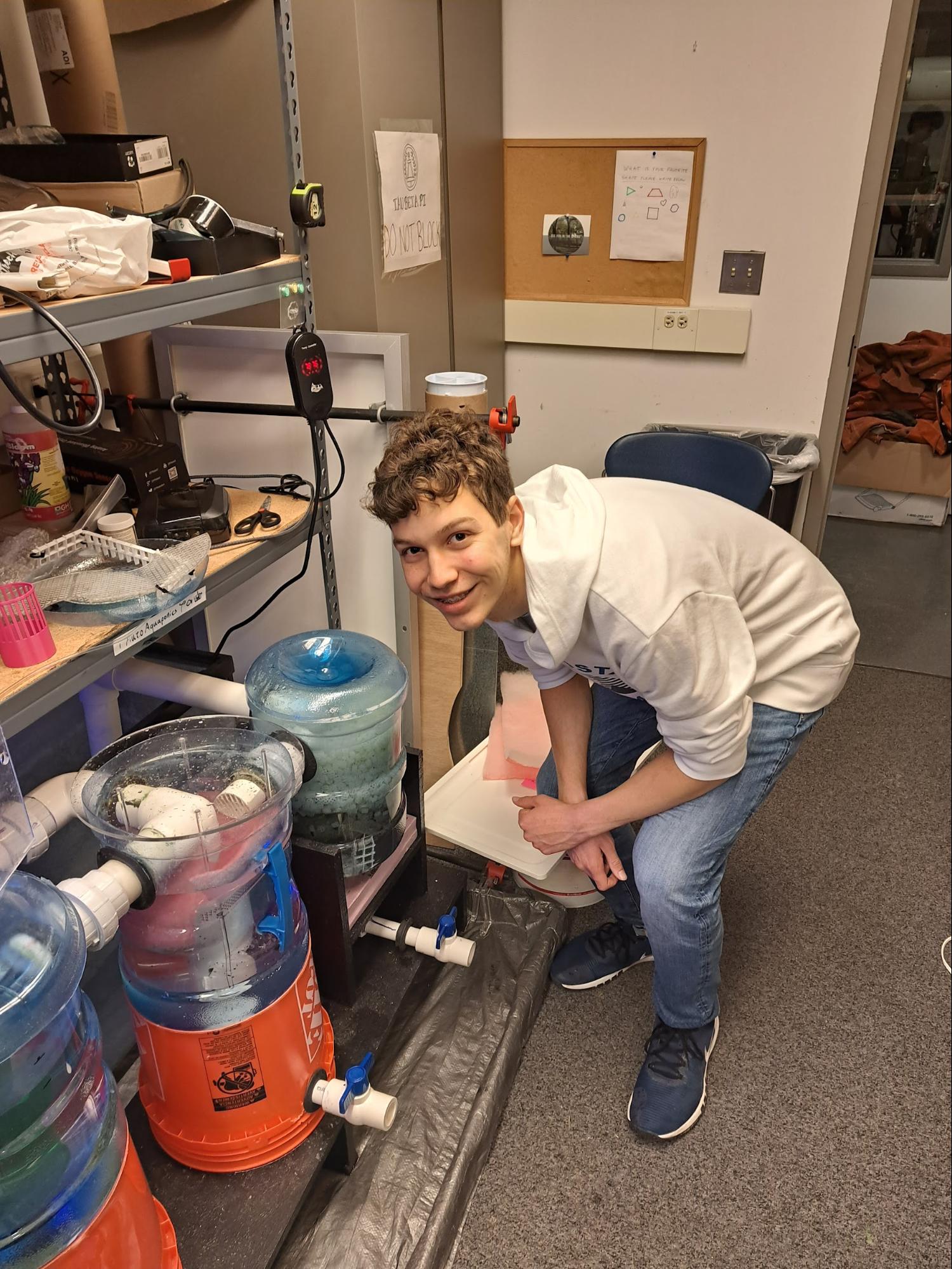

To evaluate the conversion of ammonia to useful nitrates and ensure fish and plant health, the plumbing team decided to add another dissolved oxygen(DO) sensor to the aquaponic system. Workflow has been automated and is now conducted by the biological team.

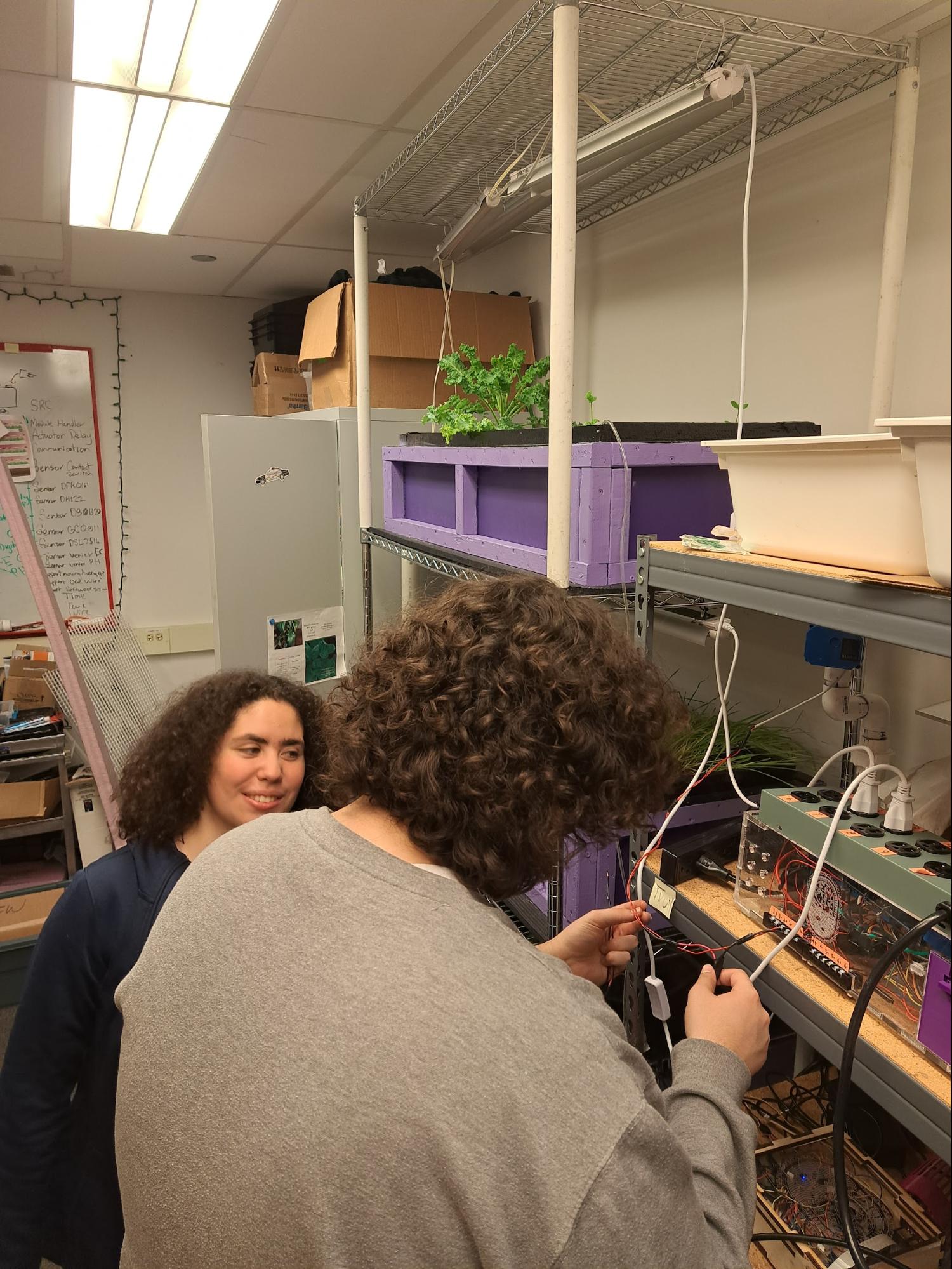

Hooking up the sensor to the sensor box for readings:

Experimenting with the readings from the DO sensor:

Because our team ran into issues with refilling the sump tank, we came up with a method to get water from the sink one room over (thanks to the NU Formula team for letting us use their room!) instead of carrying buckets of water from the bathrooms.

Algae also plagued the system over the summer, which was a cause for concern. Our plants were not growing optimally because of it, so we got to work. The Plumbing and Biology teams worked together to find a cause and adequate solution. The combination of too much light shining on water led to algae growing on grow cubes and on growbed grow media. For this reason, tinfoil was added to grow cubes and the U-siphon height was lowered so that water is not exposed to the growbed lights. Additionally, the plumbing team reworked solids lifting outlet and membrane filtration to improve fish waste collection in the system and stabilize ammonia and nitrate levels.

Software¶

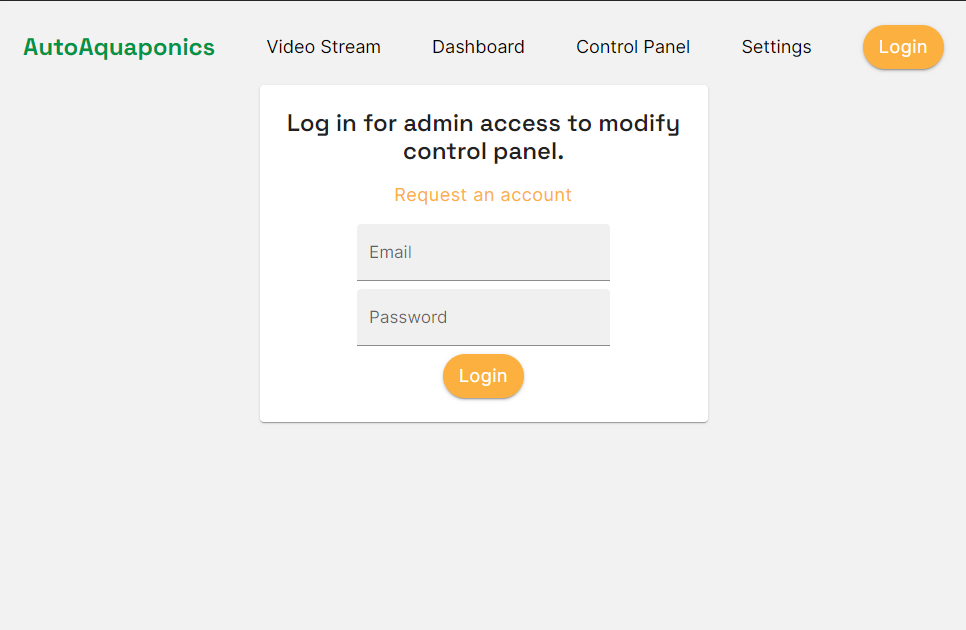

On the software side, we worked hard to improve internal workflow efficiency through a variety of means. We used GitHub releases and automated workflows to manage deployments, fixed a npm package dependency conflict by rewriting the typing animation feature, moved firebase security rules and indexes, and added script to run with emulators for backend resources for development purposes.

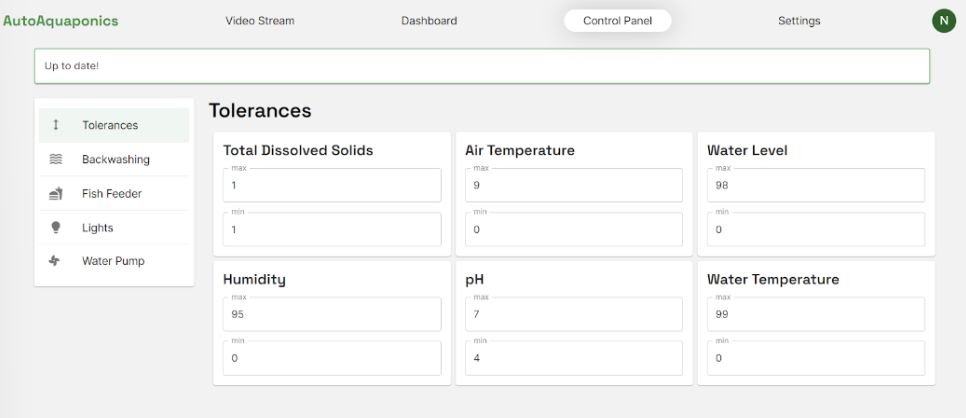

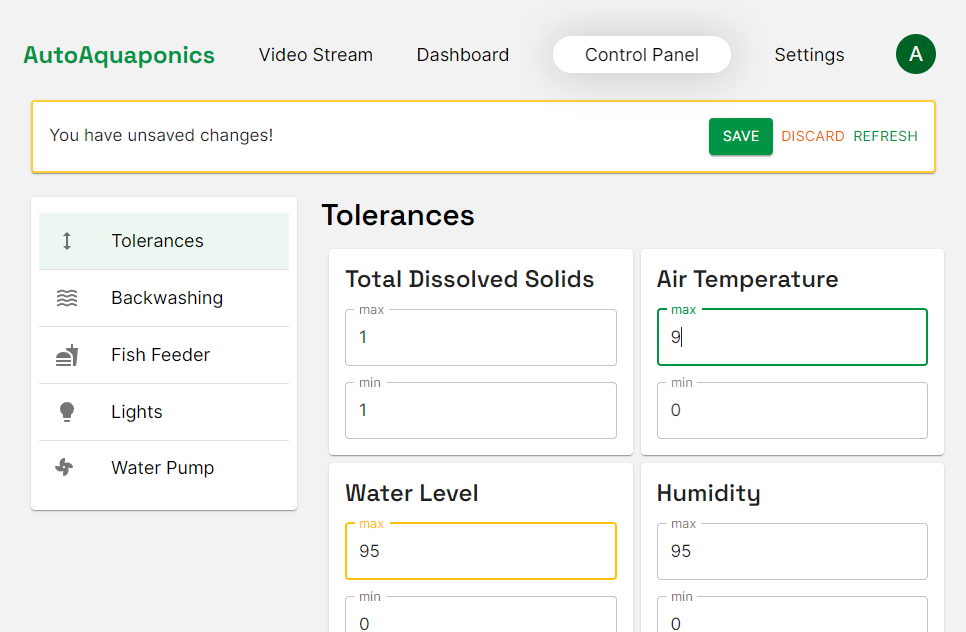

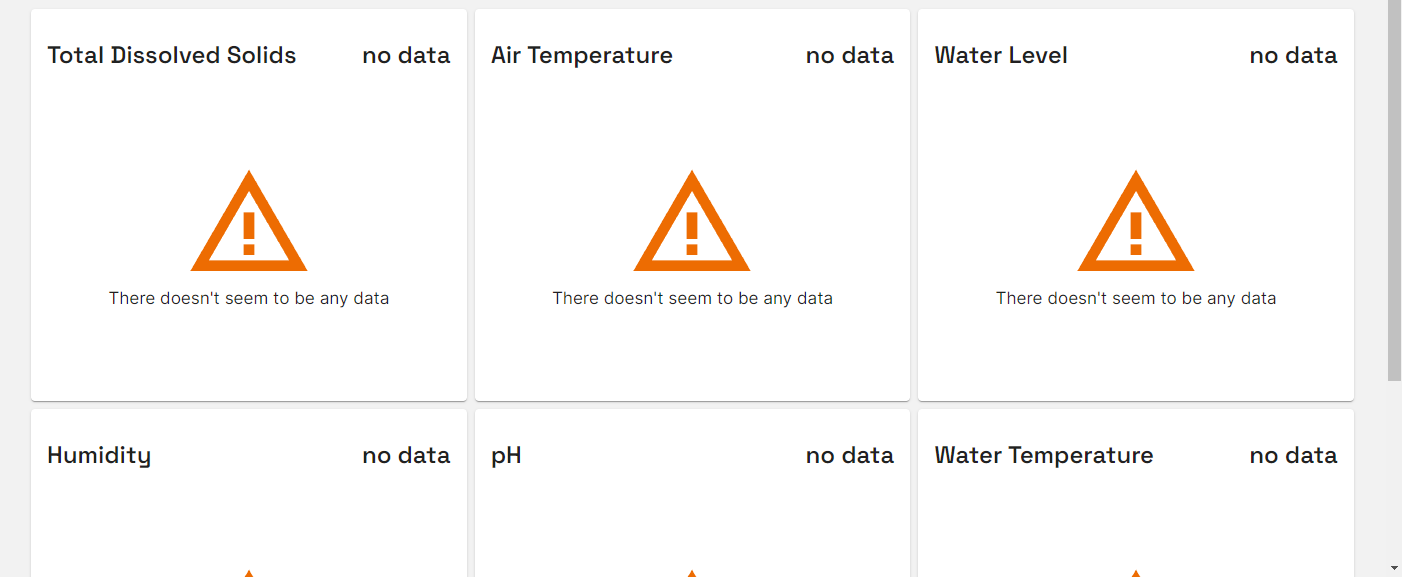

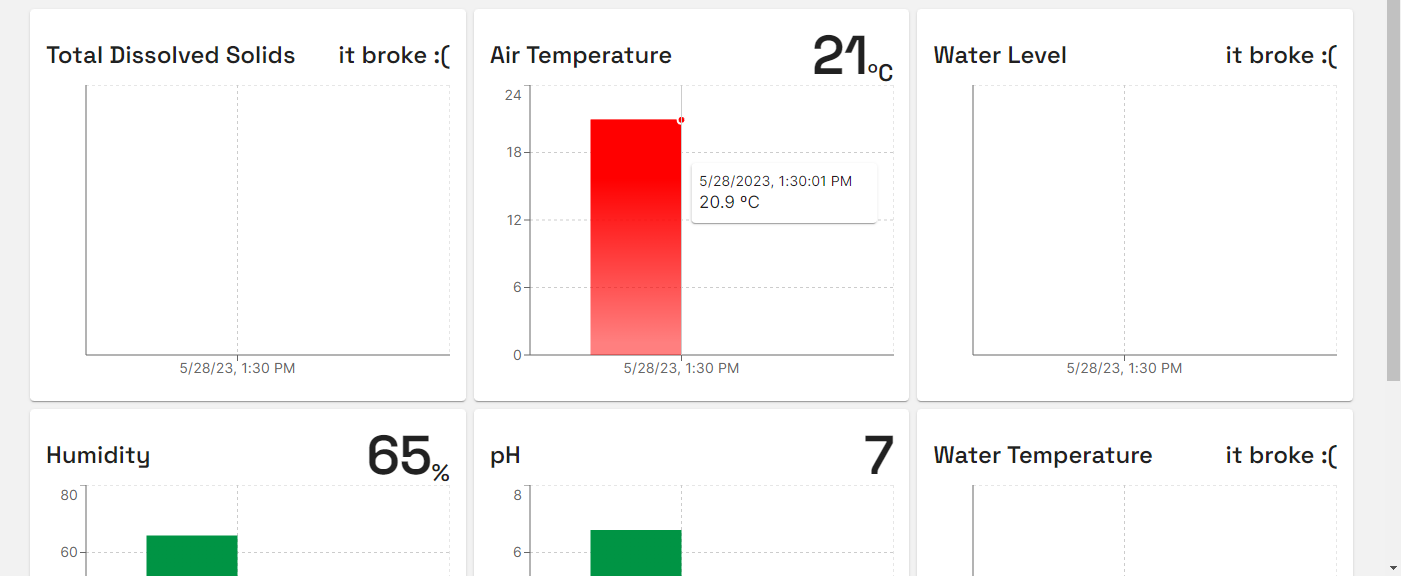

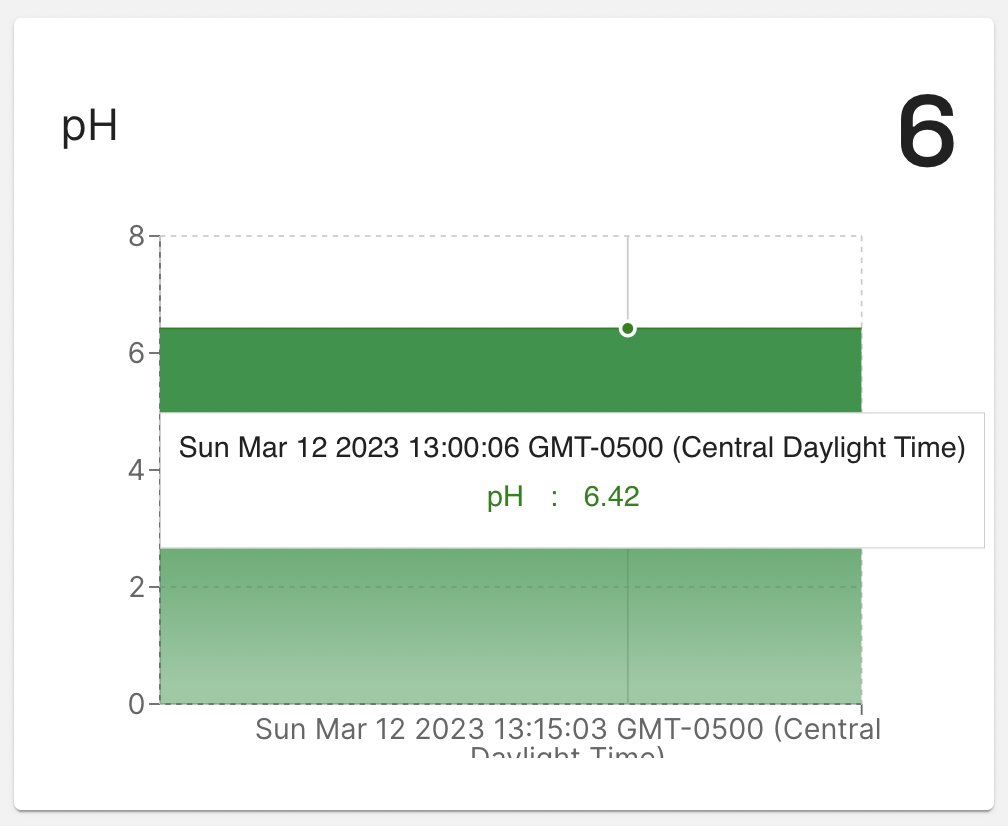

Alongside these improvements, the dashboard page and control panel now update in real time. This means that the dashboard will display data and the time updated when the system sends the data; the control panel no longer needs to refresh if other users change options. The dashboard page will no longer crash when hovering over a data point with non-existent data as well!

Control panel with no refresh button needed:

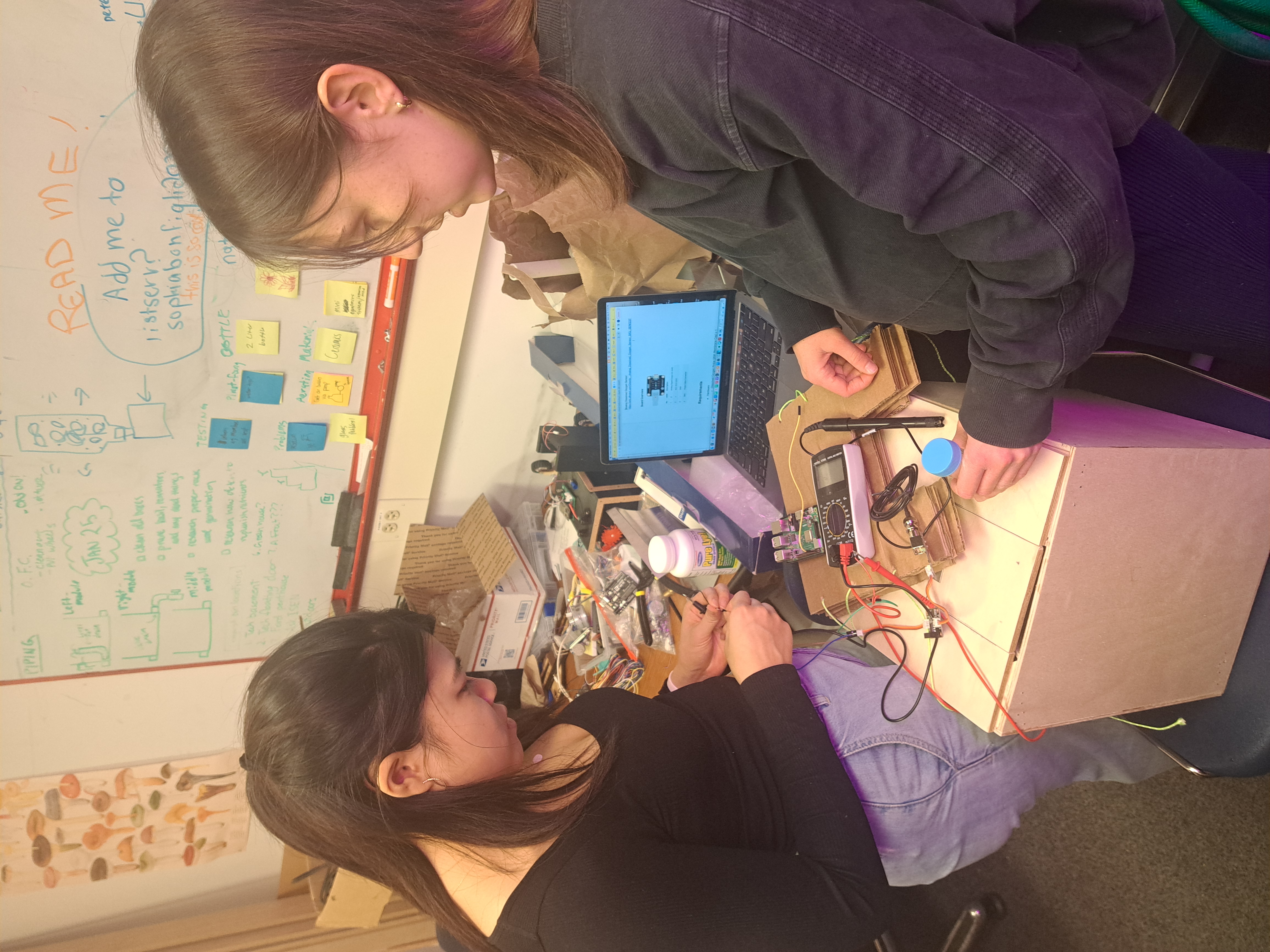

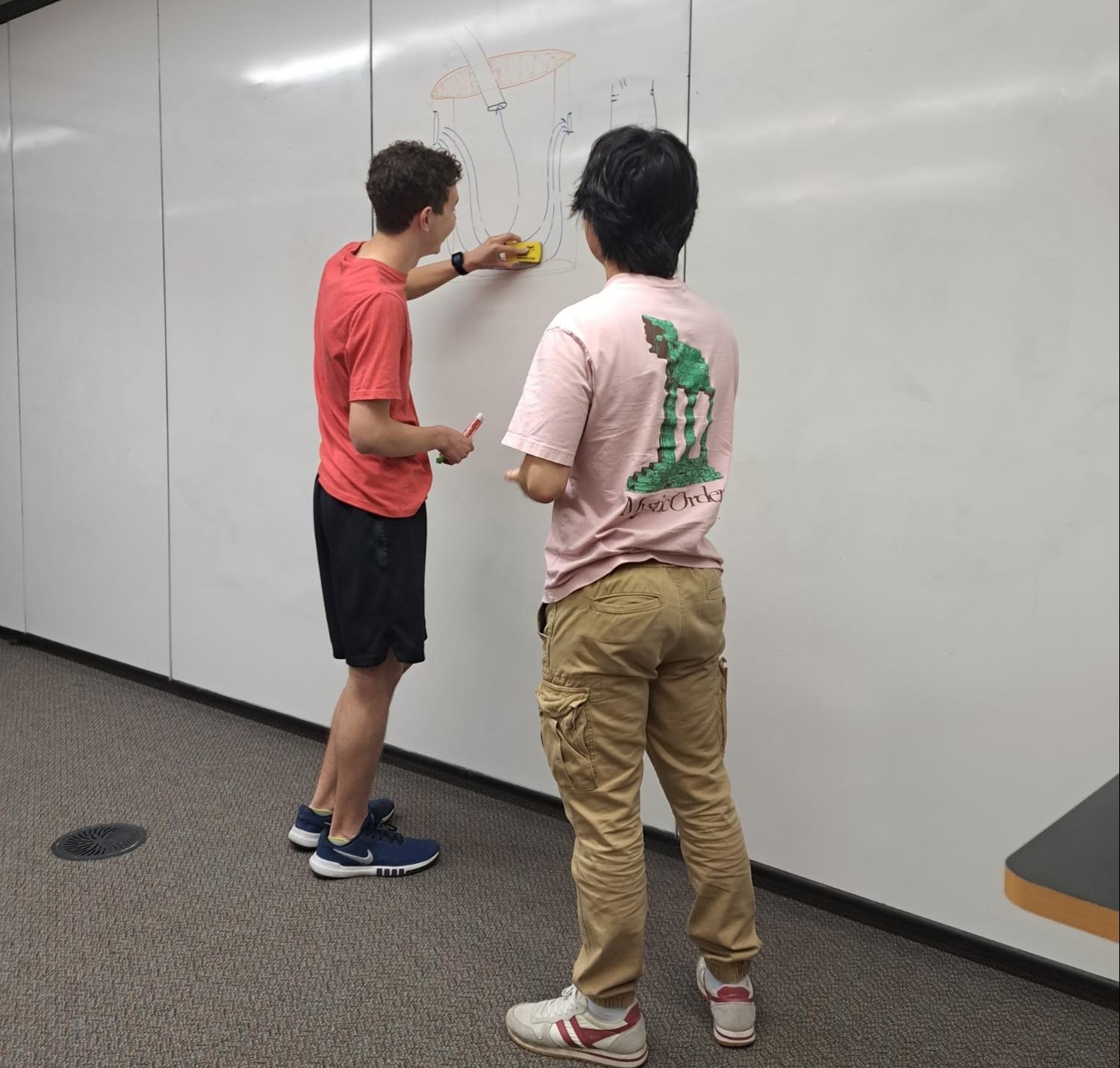

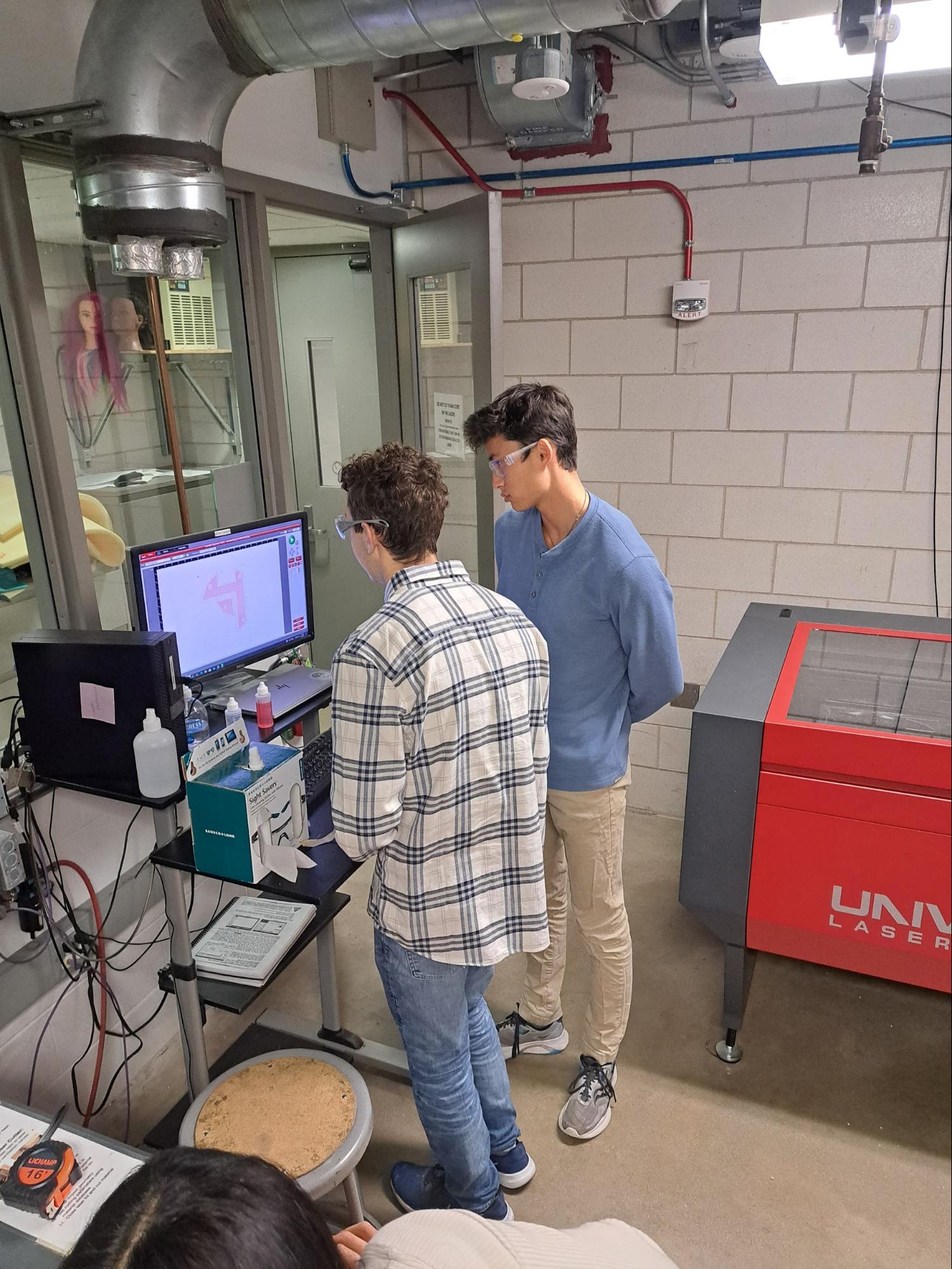

Lev and Zach making updates to the website:

Lev and Zach making updates to the website:

Electronics¶

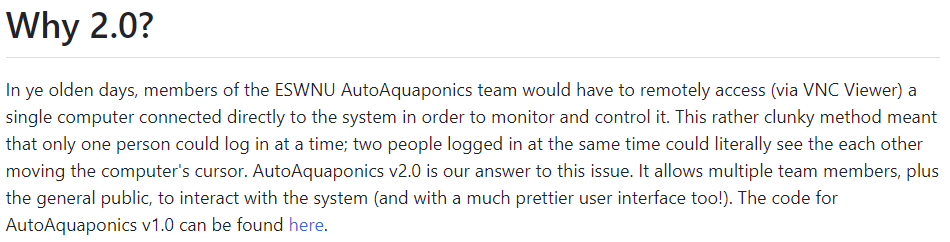

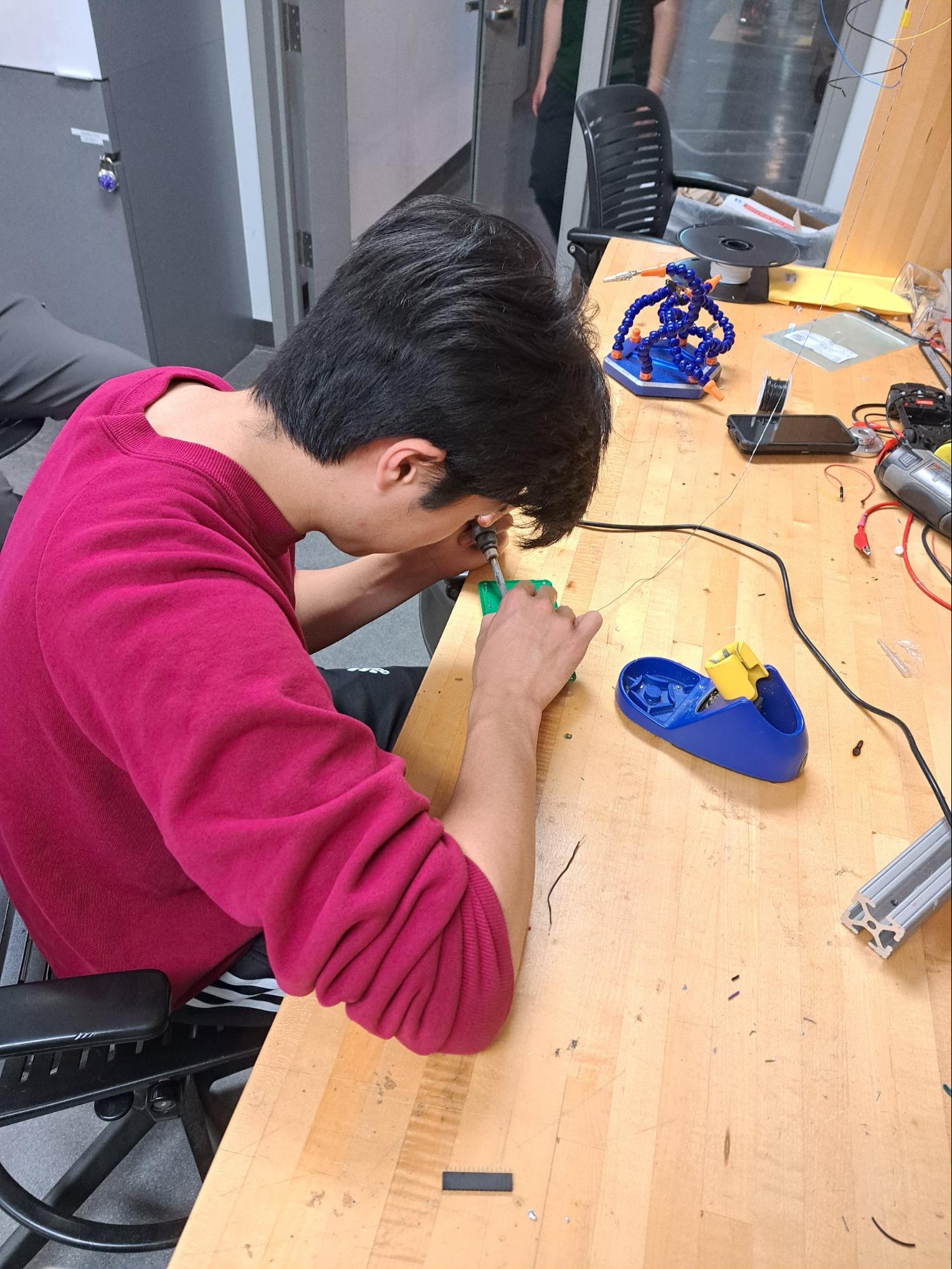

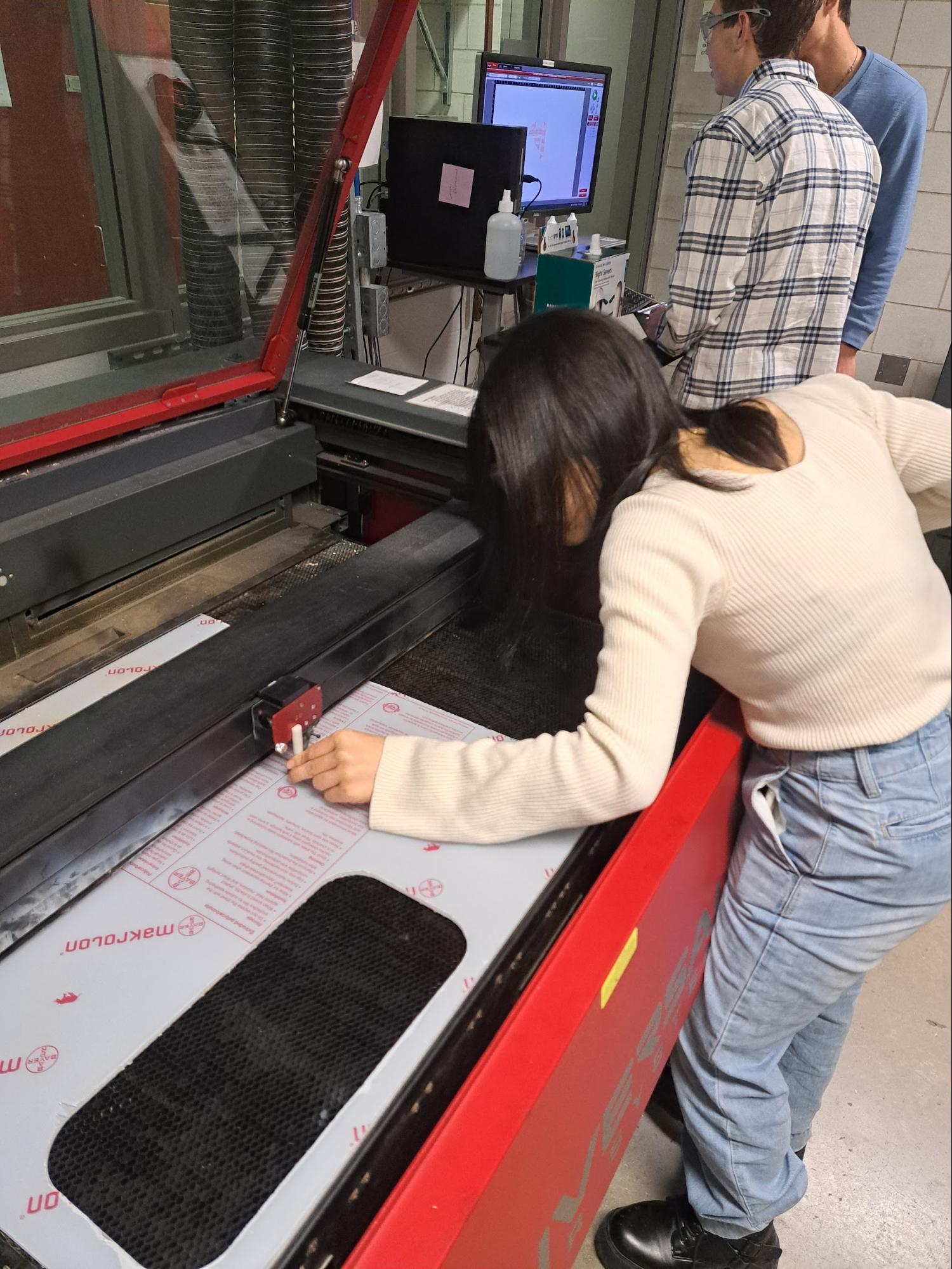

Due to a lack of personnel on the electronics team, the team paused work on the colorimeter and automatic fish feeder. Fortunately, the team managed to work on transferring the sensors to our newly developed PCB board now that we were able to get wires necessary to hook up the sensors. Next quarter, our sensors will be back online and will be able to monitor the system remotely again.

Our members also continued work on a window-cleaning robot from Spring and the outlet box code to improve its function. By the end of next quarter, we should have these tasks completed!

Biology¶

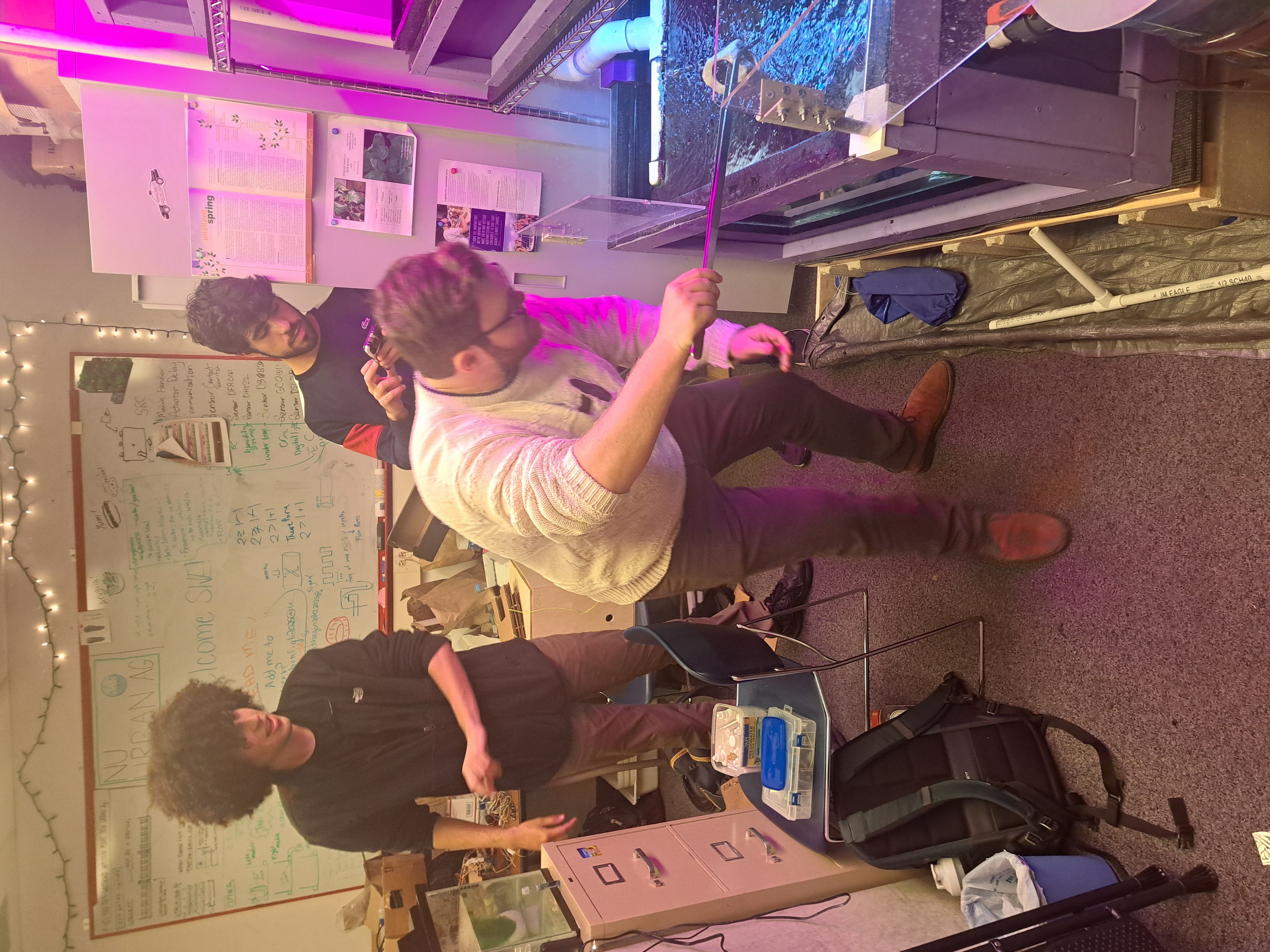

In terms of biology, we welcomed 6 new fish(tetraquads and guppies) to the tank after we set up our quarantine tank!

Along with new fish, our team aquascaped by adding decorations to the tank. Our fish now have more hiding spots and variety to enjoy.

Adjusting decorations in the tank:

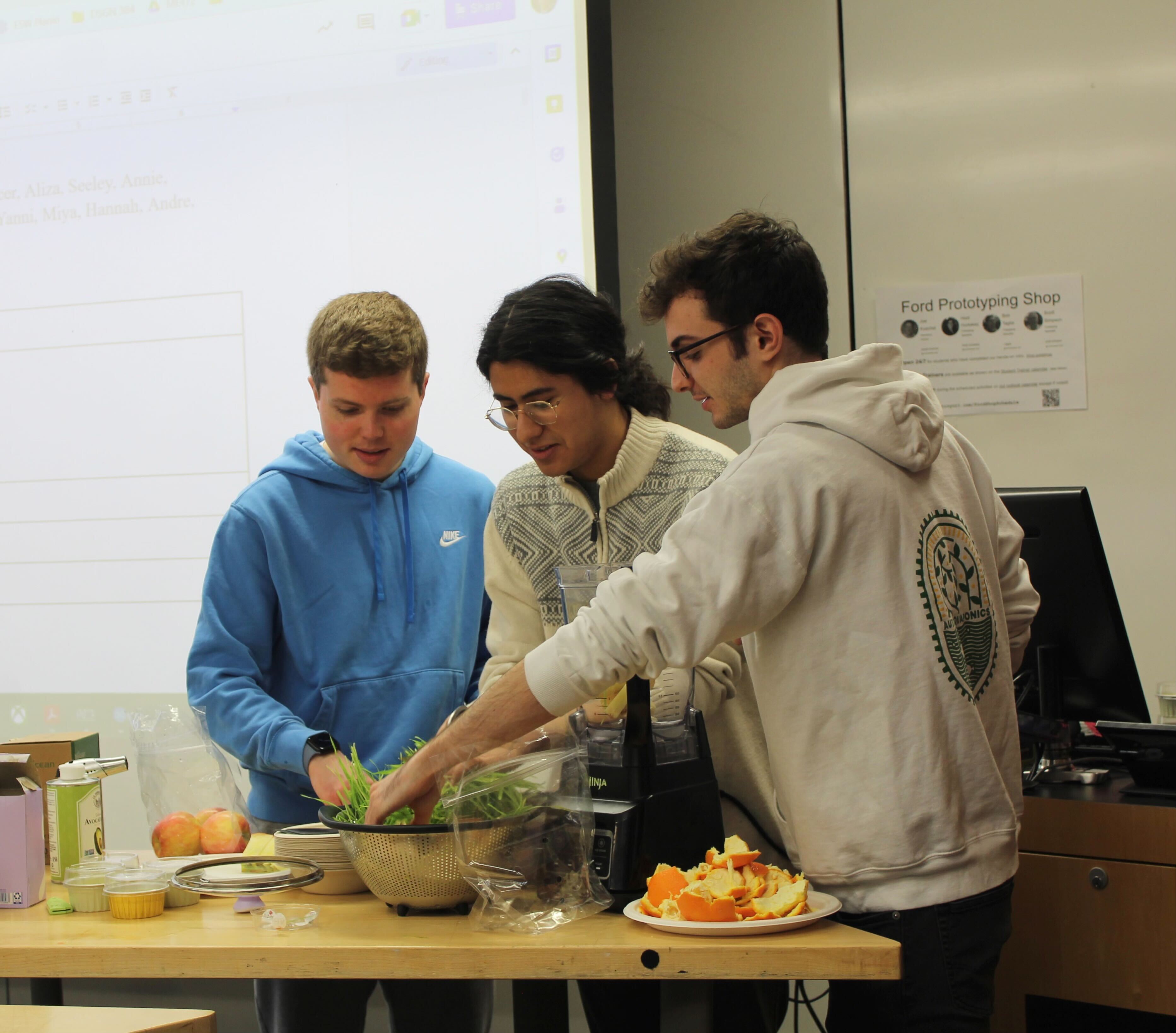

The team attempted to grow kale, basil, mint, spinach, and radishes and successfully harvested said kale, basil, and mint. Unfortunately, the spinach and radishes did not grow in the system, but we have identified the grow cubes as the point of failure. In the future, we now know how to avoid these growth problems.

Smell ya later!¶

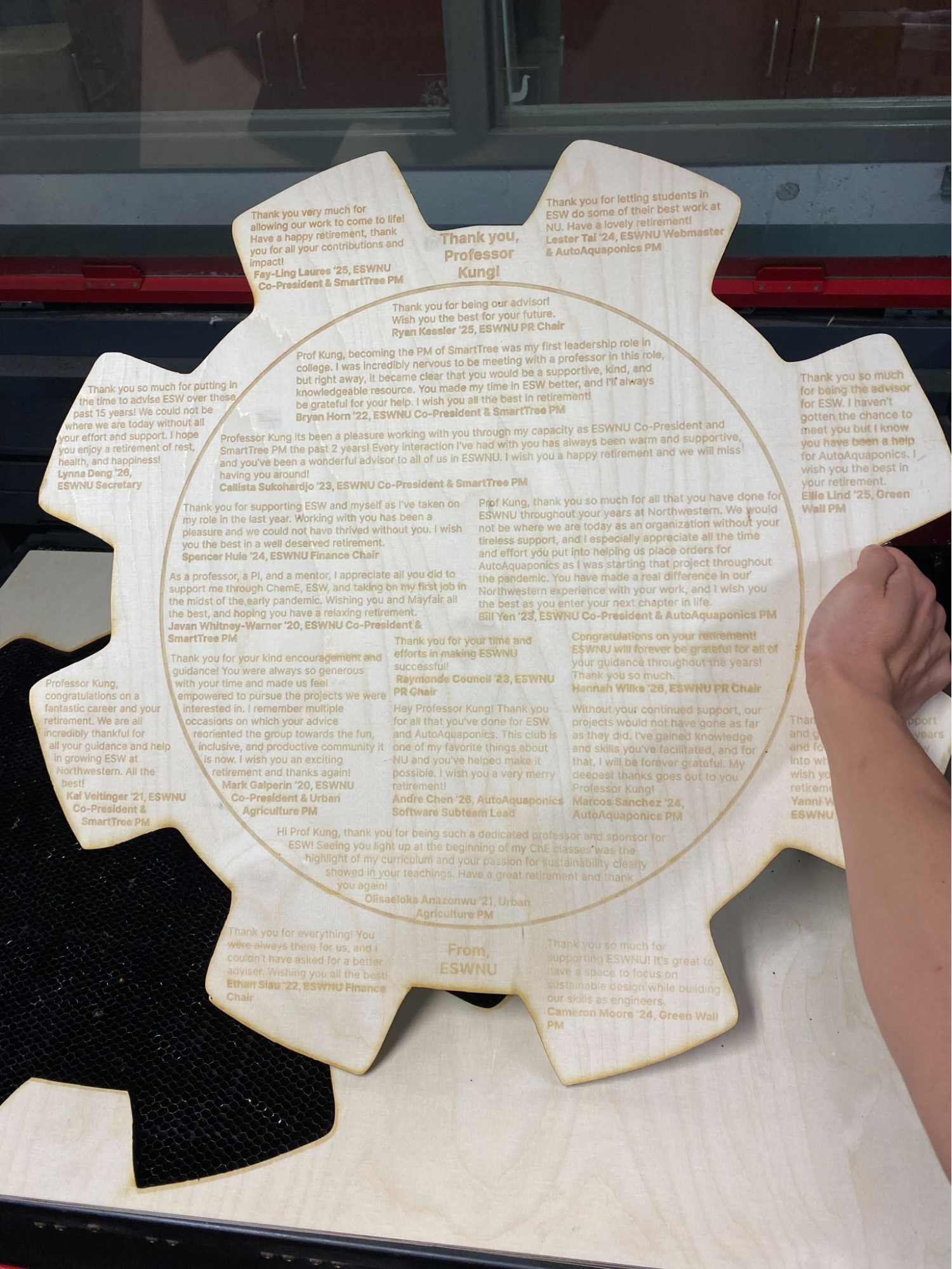

With a heavy heart, we said goodbye to Lester Tai as one of our project managers at the end of the quarter. From 2022, Lester worked tirelessly for the greater good of the club- first as a software team member and later as project manager. A Chicago native and one of the zaniest members of the team, he provided a reliable source of knowledge and labor for our electronics and software teams. We couldn’t have reached milestones without his enthusiastic support and will always remember his wide grin and clever jokes during meetings. Although he's stepping down, he'll back in the spring. It's more of a smell-ya-later than a goodbye for now, so you might see him in the spring quarter blog :) We wish him the best of luck at his Co-op and will miss him dearly!

With all that being said, we are proud of our progress this year and excited to see what the new year brings. Hope to see y’all there :)

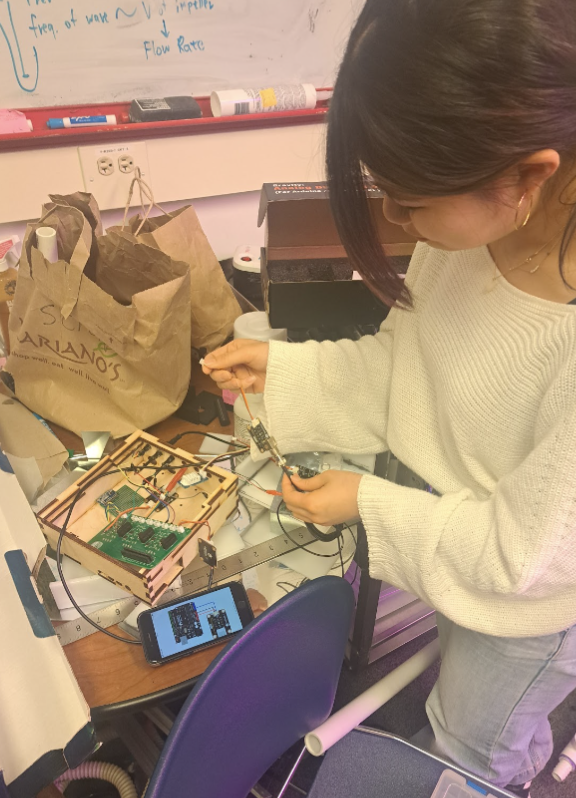

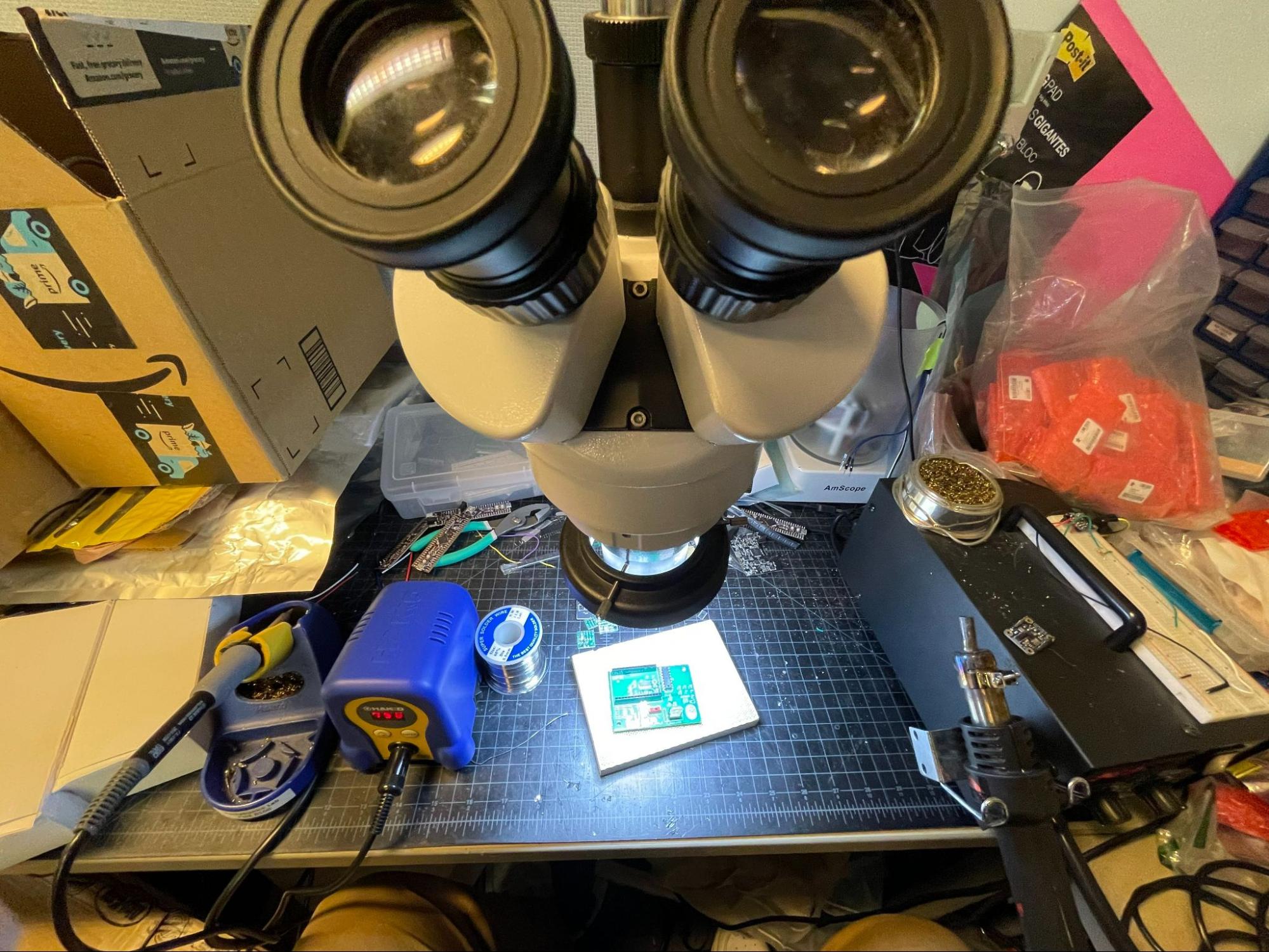

Intense discussion on how to adjust RGB values to output the correct color

Intense discussion on how to adjust RGB values to output the correct color Tinkering with the colorimeter code

Tinkering with the colorimeter code

Comments