Winter 2021 Update

Winter 2021 Update

AutoAquaponics Progress From Winter of 2021

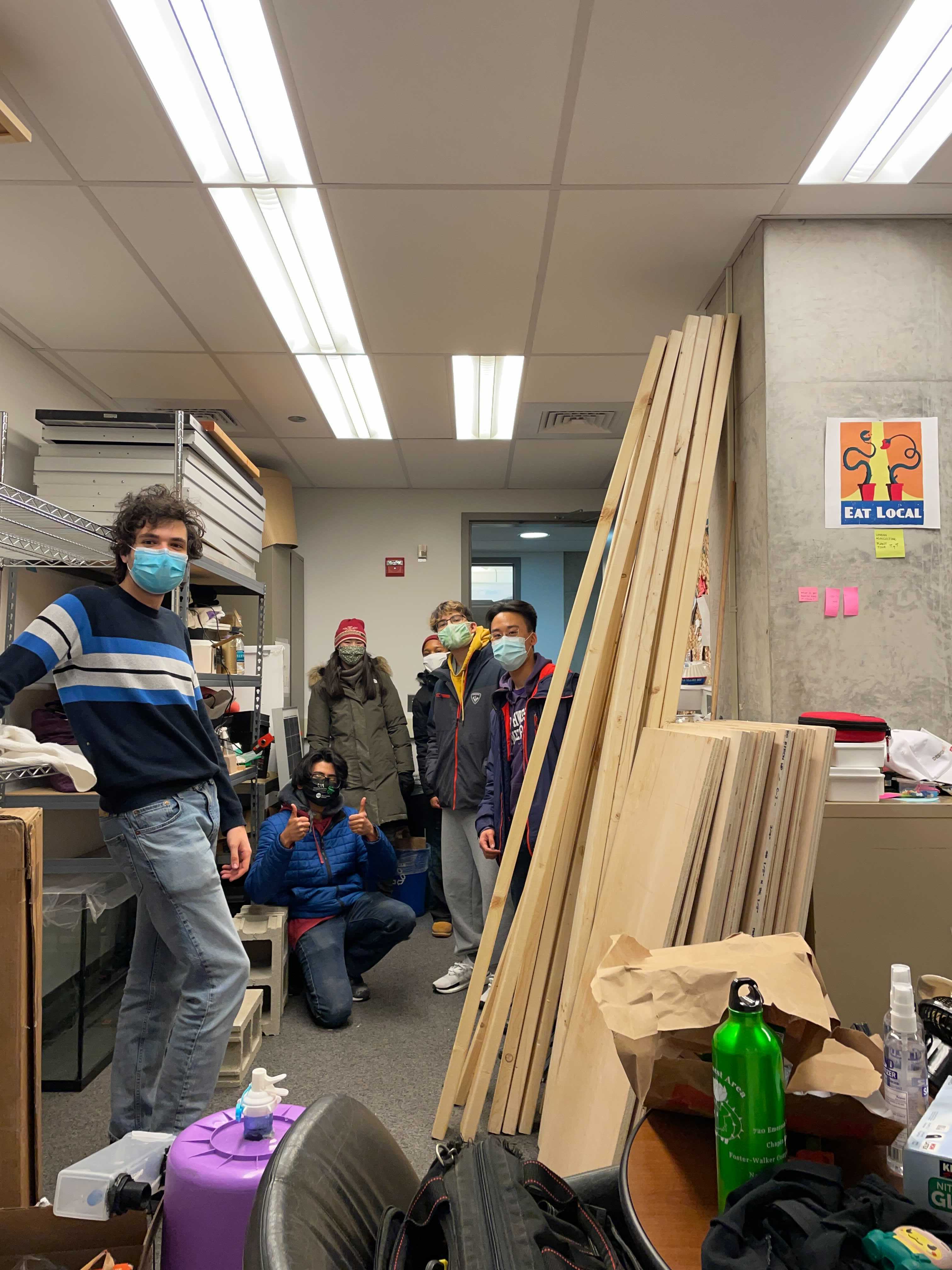

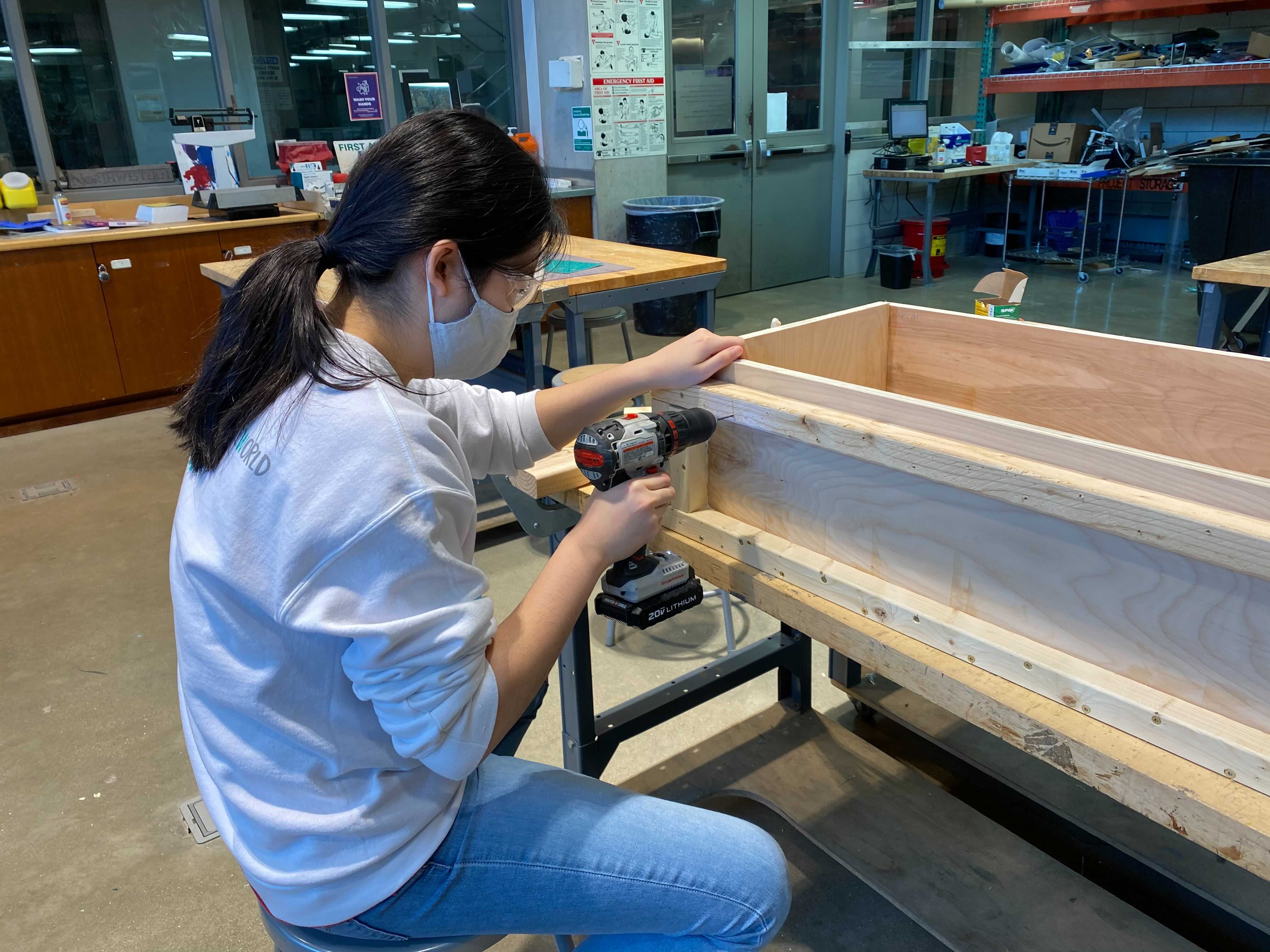

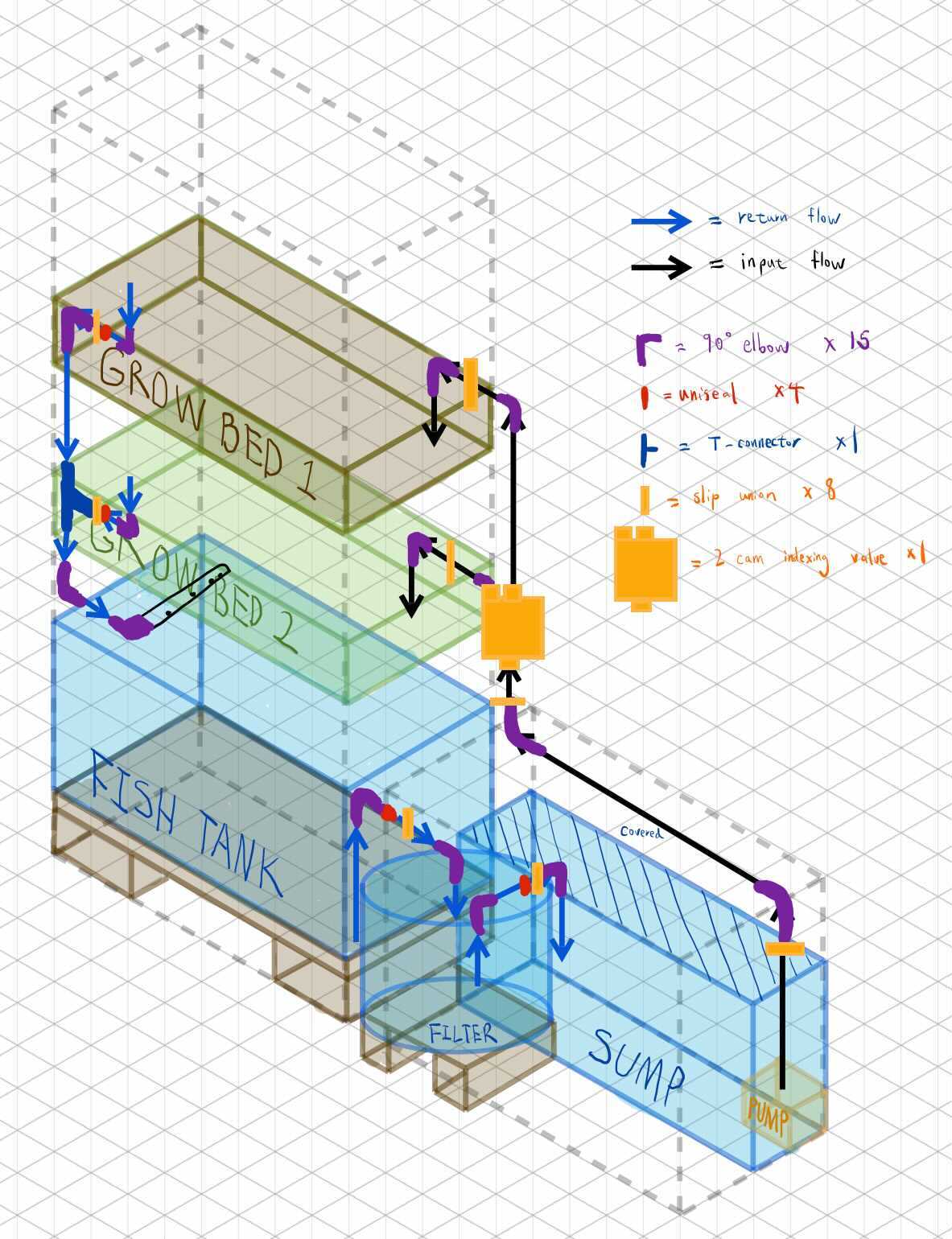

Now that the majority of our team members have returned to Northwestern's campus, AutoAquaponics has shifted its focus to building the plumbing and electronics portion of this project. We also welcomed Marcos, Anna, and Kaitlyn to our team, and we were thrilled to have them join this quarter and contribute to AutoAquaponics both virtually and in person. As a result of everyone's effort, we successfully manufactured two 24 gallon grow beds out of lumber and plywood. In Spring quarter, we will coat the grow beds with epoxy to waterproof them and get them ready for our plants, and build a much larger, 110 gallon container out of glass and wood for our fish tank.

Everyone helping to clear out space and unload materials for our system:

Team members working hard to build the two grow beds:

Completed product:

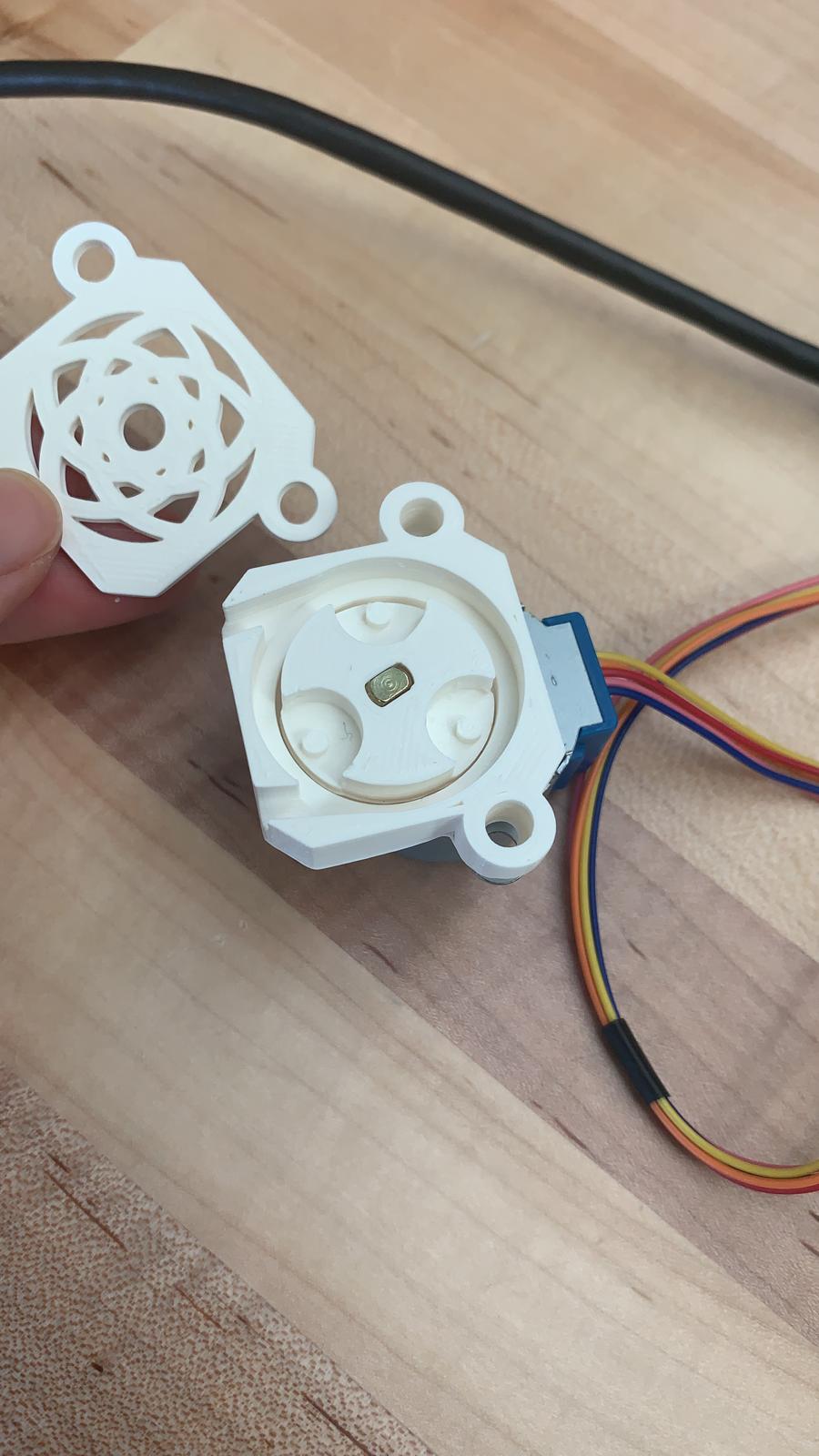

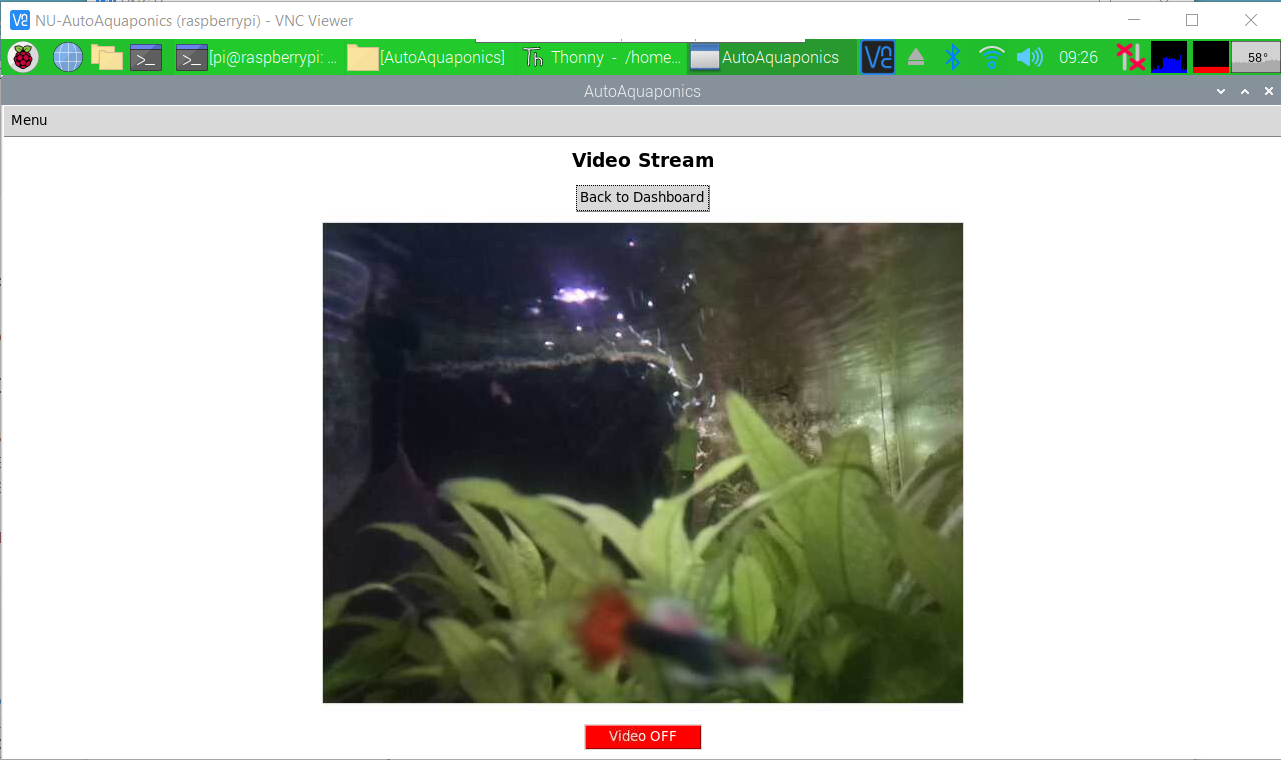

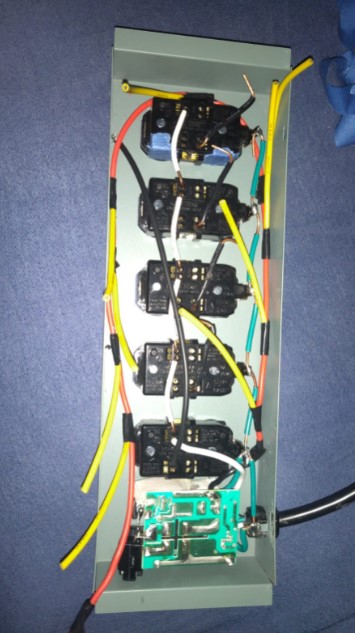

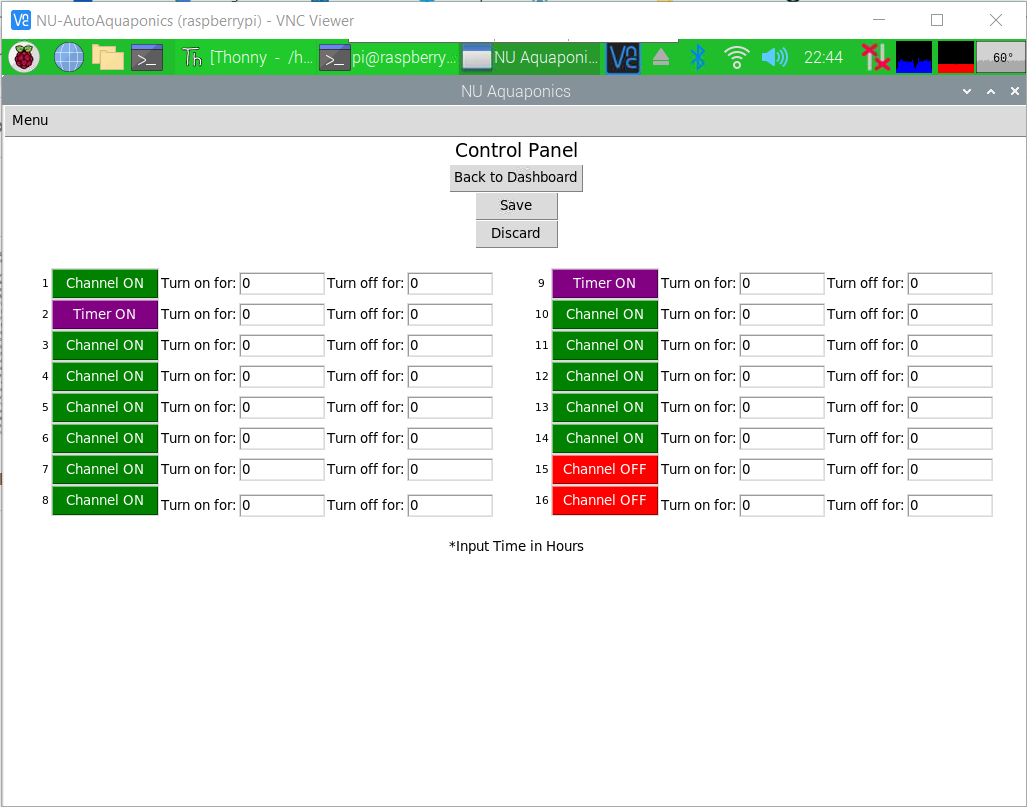

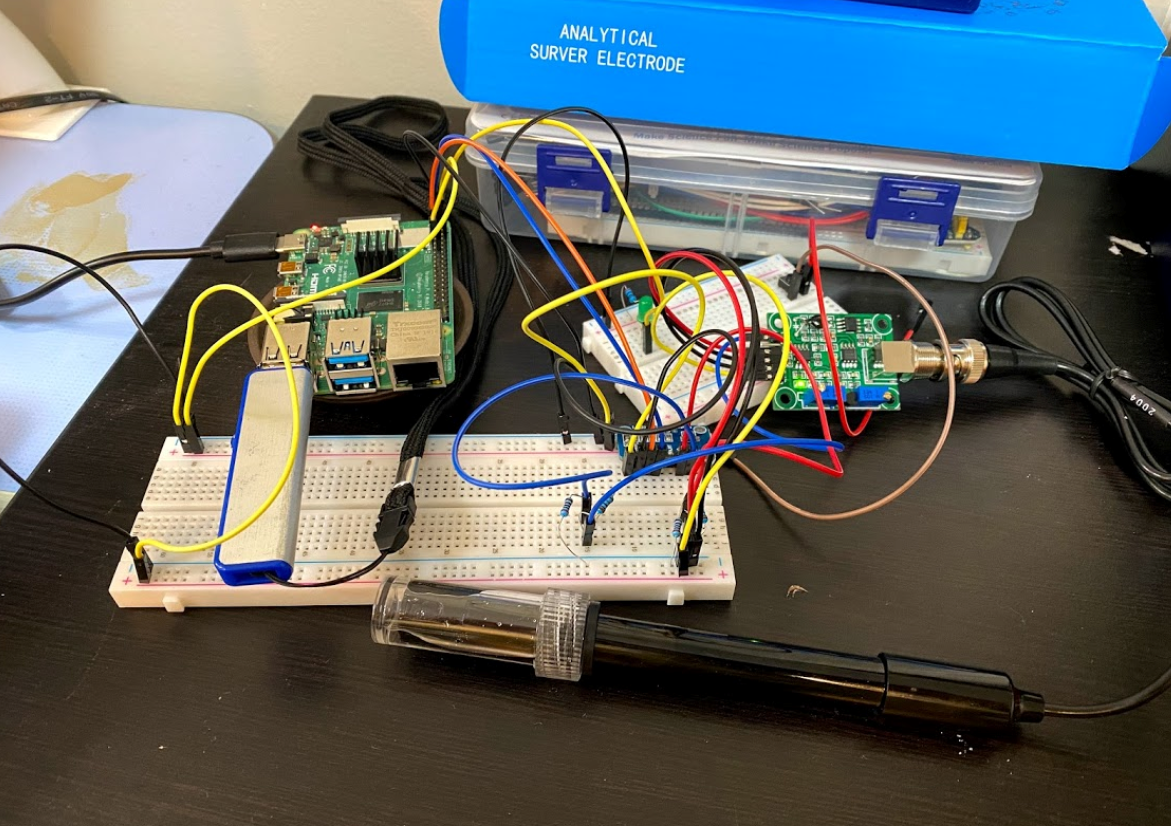

On top of plumbing construction, we also continued developing the electronic hardware portion of AutoAquaponics, namely a remote controlled outlet strip and an automatic water tester. Next quarter, we will aim to integrate these to our Raspberry Pi's GUI program by having the Raspberry Pi communicate with a number of ESP32 microcontrollers via Bluetooth Low Energy (BLE). As a result, we will be able to cut down on the amount of hardwiring we have to do and have a more modular and reliable system.

3D printed prototype of a peristaltic pump that can dispense very precise amount of water:

Raspberry Pi controlled outlet strip turning grow lights, heaters, and fans on and off fully automatically:

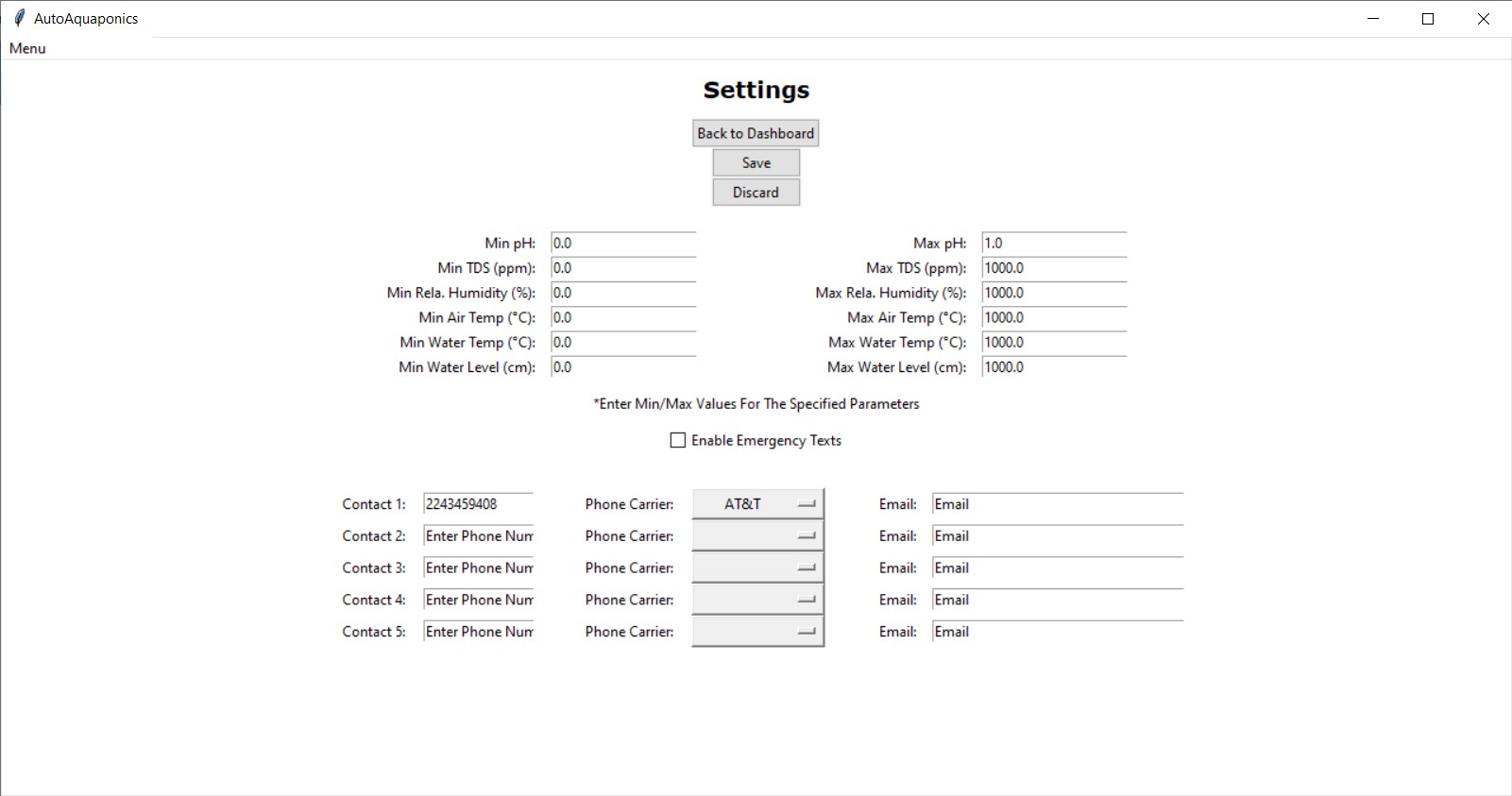

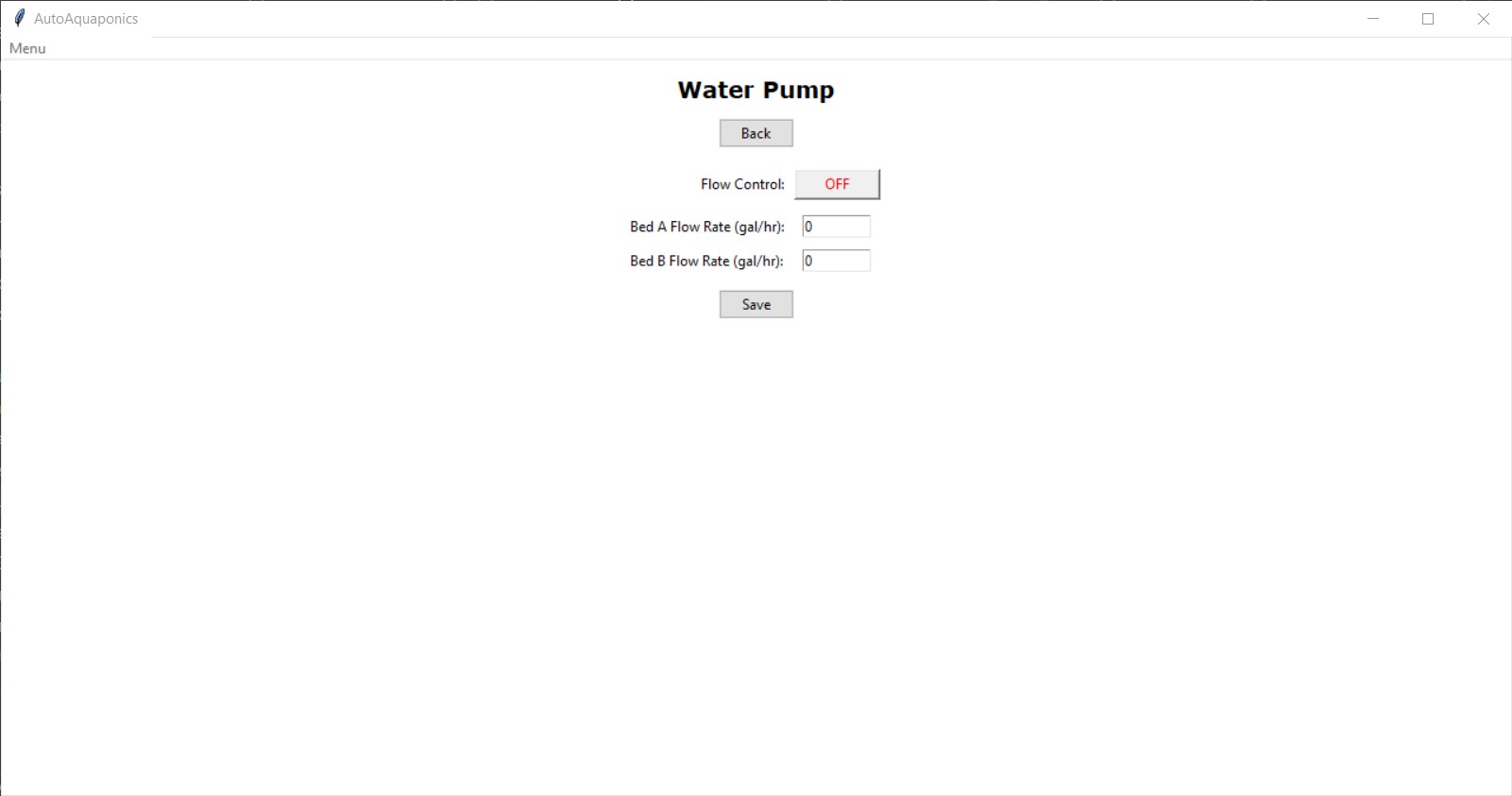

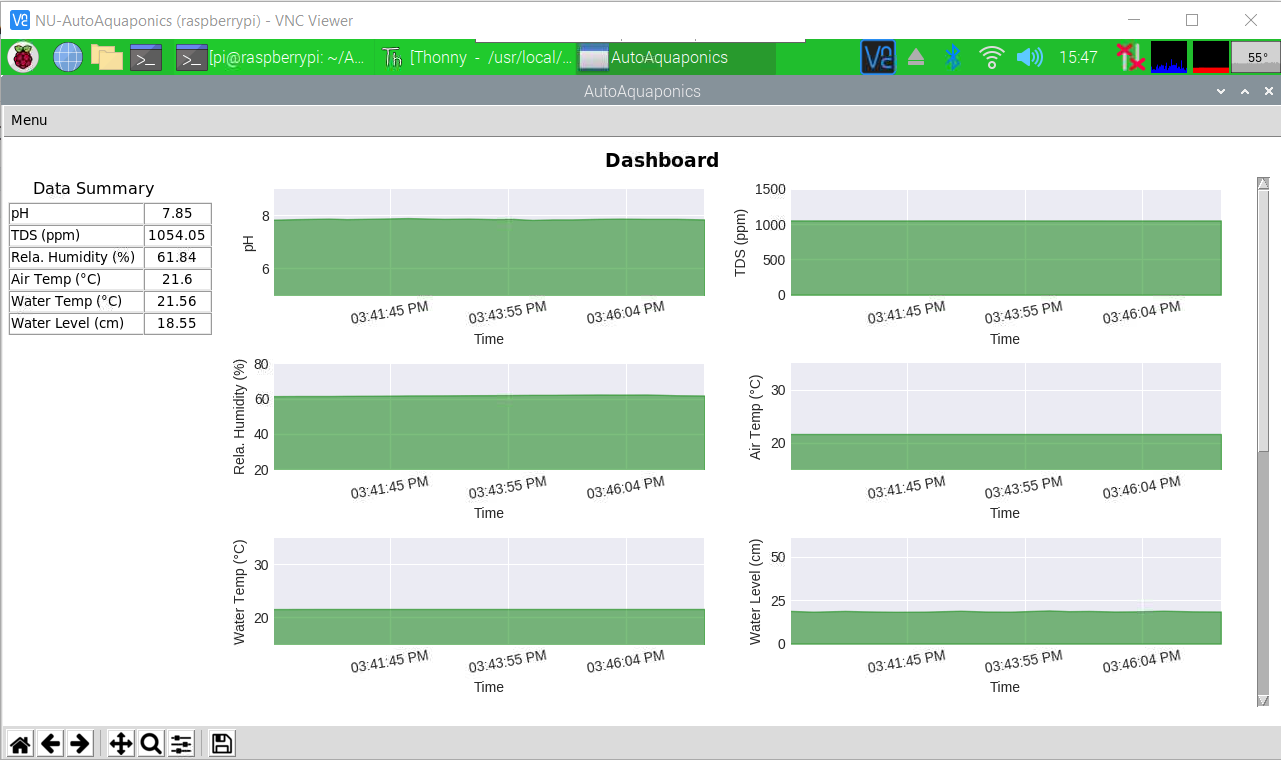

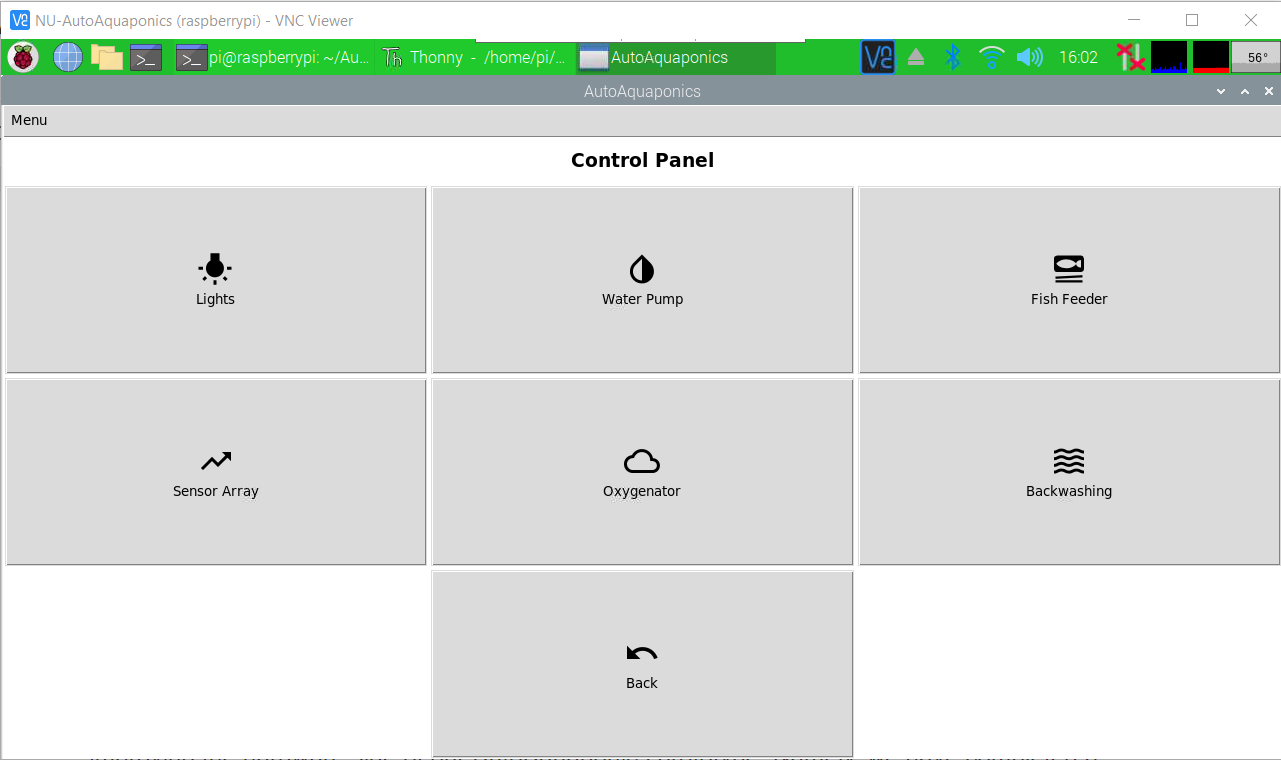

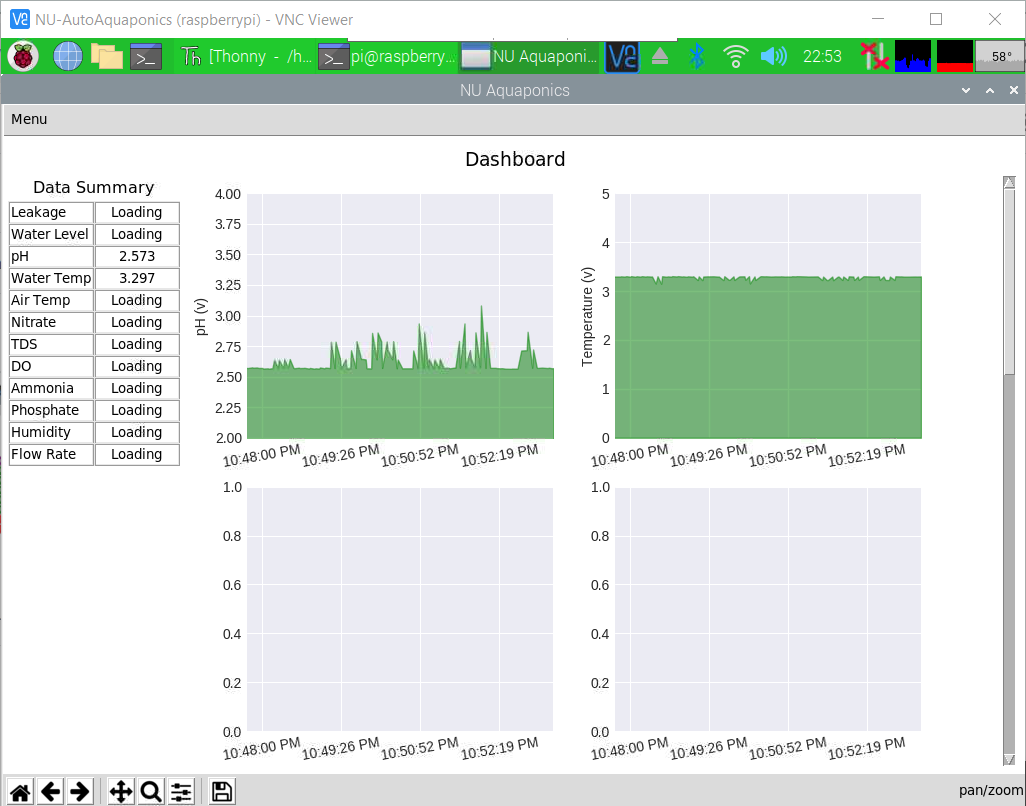

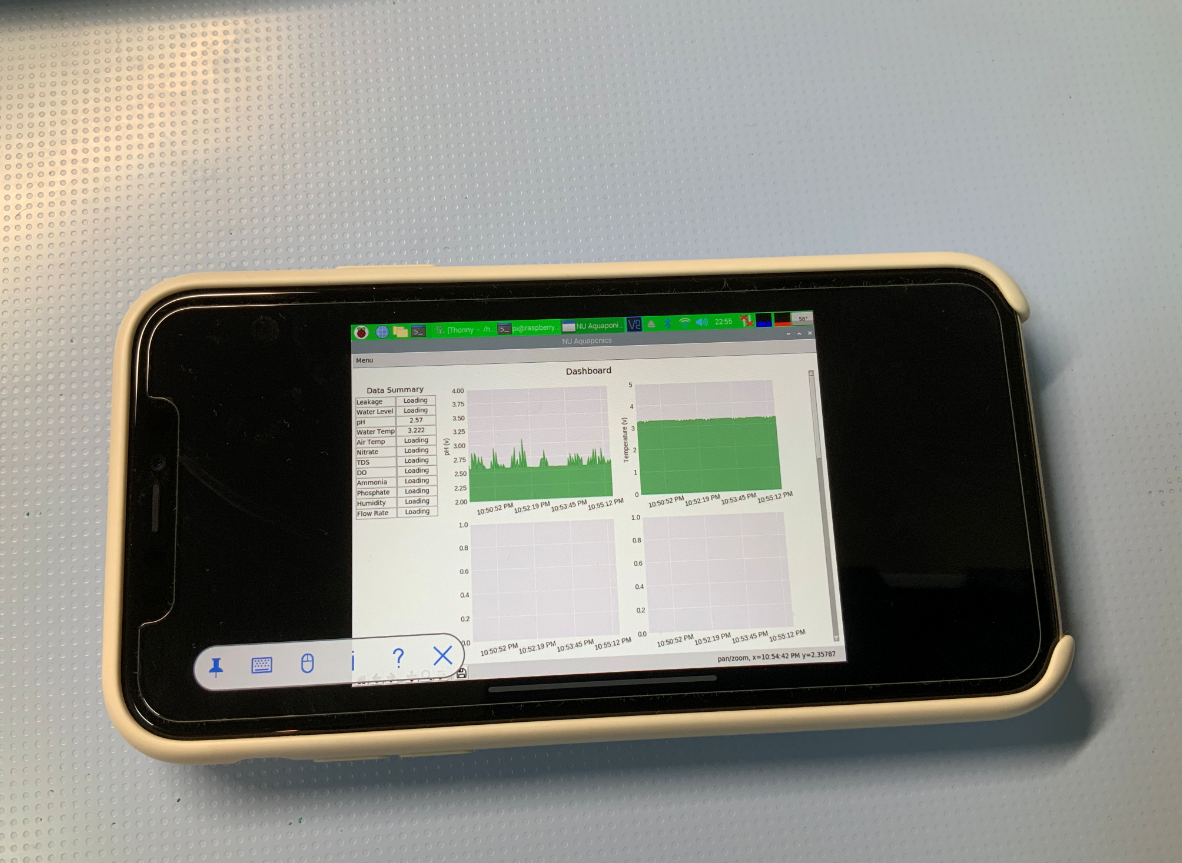

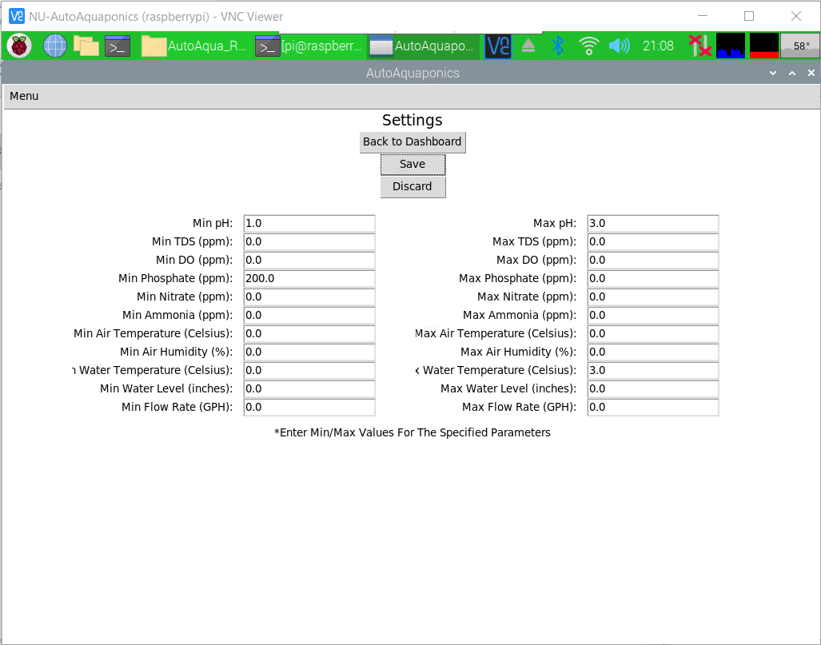

While the Plumbing and Electronics team rolled up their sleeves for construction, the Software team continued to add more functionalities to the AutoAquaponics GUI. This quarter, we completed the Settings page of the program, which allows the user to specify their preferred environmental parameters, and receive text messages when the detected parameters are not within the "safe" level. They can also enter their email to receive a weekly summary of what the state of the system is. In addition, we began adding subpages that the user can use to control the actuators in the aquaponic system. Eventually, we plan to have one subpage per actuator in the system so users can change their settings to whatever they like without needing to code.

Completed Settings page:

Water Pump page users can utilize to control the system's water pump:

Thanks for reading, and keep an eye out for more from NU AutoAquaponics next quarter!

Comments