Fall 2024 Update

Fall 2024 Update

Fall 2024 update for AutoAquaponics @ Northwestern University. We built a lot and welcomed a lot of new members!

We had an absolutely lovely fall quarter in AutoAquaponics this year. We grew our subteams, had a successful harvest, cleaned the whole system, and worked on/started a ton of exciting new projects. Kyan and I are super excited with the progress this team has made and the new things coming in the future!

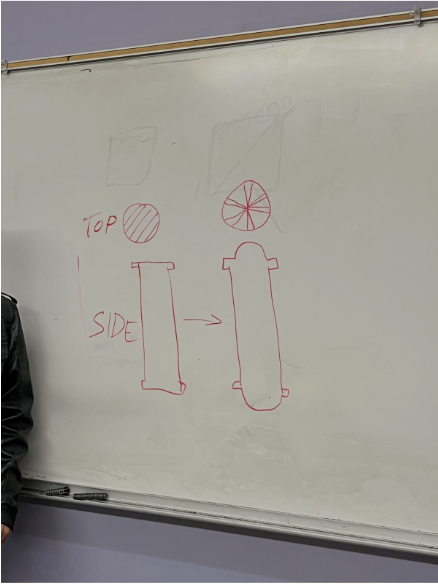

Our mechanical design team had a productive quarter. With a whole group of new members, we had exciting system upgrades like redesigning the SLO pipe caps to prevent flow restriction and updating the CAD of the whole system to include the new growbeds and make overall improvements to the CAD system according to mechanical engineering standards.

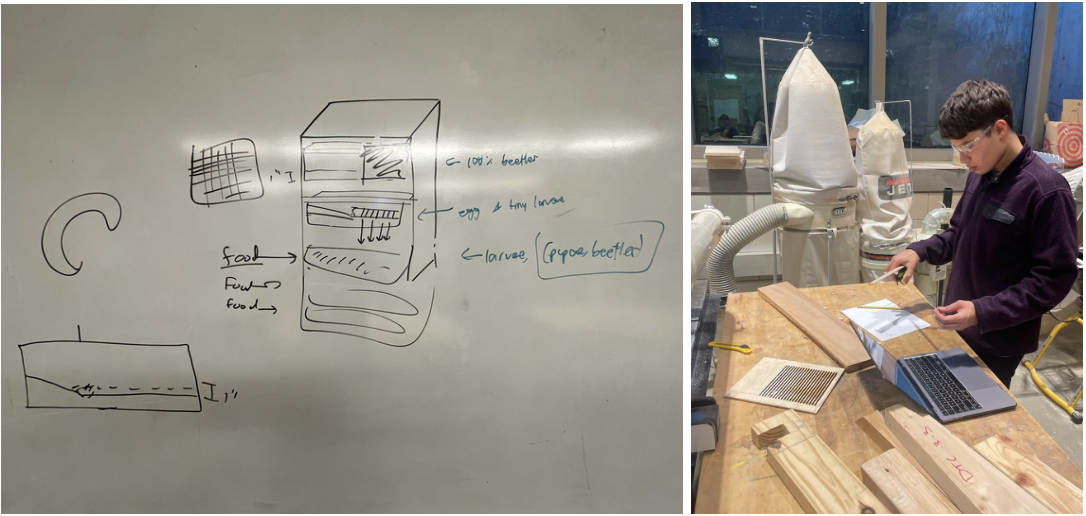

Speaking of the new growbed, the mechanical design cut the wood and assembled two faces of the new bed! While we wait for access to a large hole saw, production has paused for the bed until after break. But, the team printed attachments and inserted PVC pipes to extend the frame of the right shelf so that there is space for the new growbed, so we are all set to go when that is built!

In other growbed news, the team cut the PVC pipe and drilled holes for the new hydroponic vertical growbed. The water height adjusters are in place with epoxy sealant and have been tested to raise water levels in an ebb-and-flow system. An additional part was designed and tested to prevent backflow at the 1-inch to 3-inch reducers that inlet to the vertical growbed.

To further improve the sustainability of the system, Santiago has designed and tested Mealworm-Pupae filtration grates, designed an automatic and self-sustaining mealworm farm, and built up a large population of mealworms. We are hoping to close the fish-feeding food loop this upcoming quarter with the mealworms by automating mealworm production.

To further improve the sustainability of the system, Santiago has designed and tested Mealworm-Pupae filtration grates, designed an automatic and self-sustaining mealworm farm, and built up a large population of mealworms. We are hoping to close the fish-feeding food loop this upcoming quarter with the mealworms by automating mealworm production.

The team is also in the final stages of rebuilding the membrane filtration tank for easier cleaning and maintenance. They finalized laser cutter tolerances to ensure walls mesh together at corners and designed a bracket and fastener system to mechanically hold the tank together and a sloped floor for proper drainage. This quarter, the mechanical design team is finishing up fasteners and finishing the laser cutting and production.

Our biology team welcomed three wonderful new members, who have all diligently helped us maintain all of the living components of the system. A huge thank you to Audrey Aishie for stepping up and leading the biology team this quarter! The team had a VERY successful kale and basil harvest and had a delicious harvest celebration.

We had some issues with the flow in the lower growbed, with a one way valve that was clogged with roots and plant debris impeding flow in the bottom growbed. We dug up the U-siphon and valve, removed all debris, and reinstalled the piping. With collaboration from the mechanical team, we adjusted the overall tank flow to reduce the flow rate and avoid tank overflows, updated bal valve electrical connections to lower the growbed so flow properly alternates between growbeds, and performed a full water change. Shoutout to Audrey, Calvin, and Kyan for spending three hours on a Saturday doing that!

We designed new decorative coral for the bottom of the tank that will not irritate the fish, as the current decorative plants are proving to be a little sharp. We are also super excited that we have dill growing in the system for the first time! We can’t wait for all of the plants that we will be growing in the winter, regardless of the temperature outside.

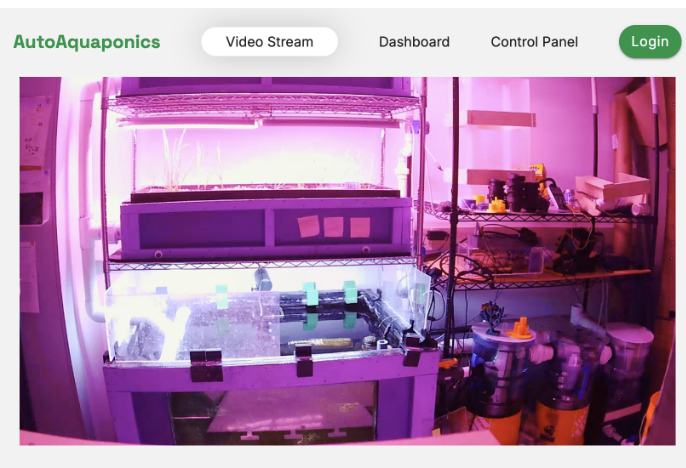

Our software team had an extremely productive quarter. We are super excited to announce that we have a livestream of the system up on the website (https://autoaquaponics.org/video-stream). It achieves far better performance and reliability than the previous ESP-32 CAM-based system and is also just so cool!

We set up a new Raspberry Pi 5! It now functions as a permanent server that can be remotely accessed. We currently have the livestream and system notifications deployed on it, anticipate reinstating sensor box functionality on it, and plan to use it as the primary deployment method for all other functionality for controlling and monitoring the AutoAquaponics system. We began work on a task-management framework for coordinating all the different functions we anticipate running on the Pi.

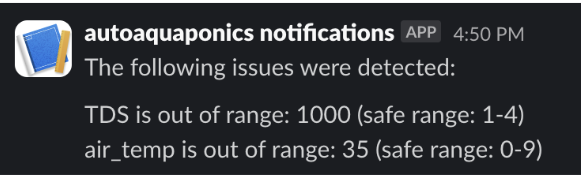

Something our PMs are super excited about is system notifications! We created a working implementation of emergency notifications that send to email, SMS, and Slack chat bot, deployed to the Raspberry Pi.

Something our PMs are super excited about is system notifications! We created a working implementation of emergency notifications that send to email, SMS, and Slack chat bot, deployed to the Raspberry Pi.

For the outlet box, our team wrote a simple FreeRTOS timer implementation that allows independent timer creation and deletion and created minimal prototypes of Bluetooth on ESP-32, using both ESP-IDF and Arduino frameworks.

For VertiGrow this quarter, the mechanical design team is updating the CAD and the software team managed to compile an image recognition model using OpenCV onto the resource-constrained ESP-32. We are excited to get this project moving once the new, larger growbed is built.

Our electronics team welcomed a new member, Christian! This quarter the electronics team focused on updating the wiring of the outlet box and updating the documentation for the electronics in the system. The team tested and got the analog sensors up and running. We are planning to get the digital sensors back online this quarter and resume collecting system data as soon as possible!

Looking forward to next quarter, we are thrilled to announce that Calvin Davies will be taking over the mechanical design subteam and Jack Doheny will be taking over the biology subteam! Thank you so much to all project members for working so hard this quarter! We are so excited to see all the new projects in action. And thank you to all who follow along to see the AutoAquaponics progress. It is never ending :)

Comments