Winter 2024 Update

Winter 2024 Update

This quarter, AutoAquaponics made headway towards our existing projects from last quarter and even began some exciting new projects! These new projects do not come for free, so we applied for and received another McCormick Student Advisory Board grant. Our sincerest thanks goes out to them for making this project possible!

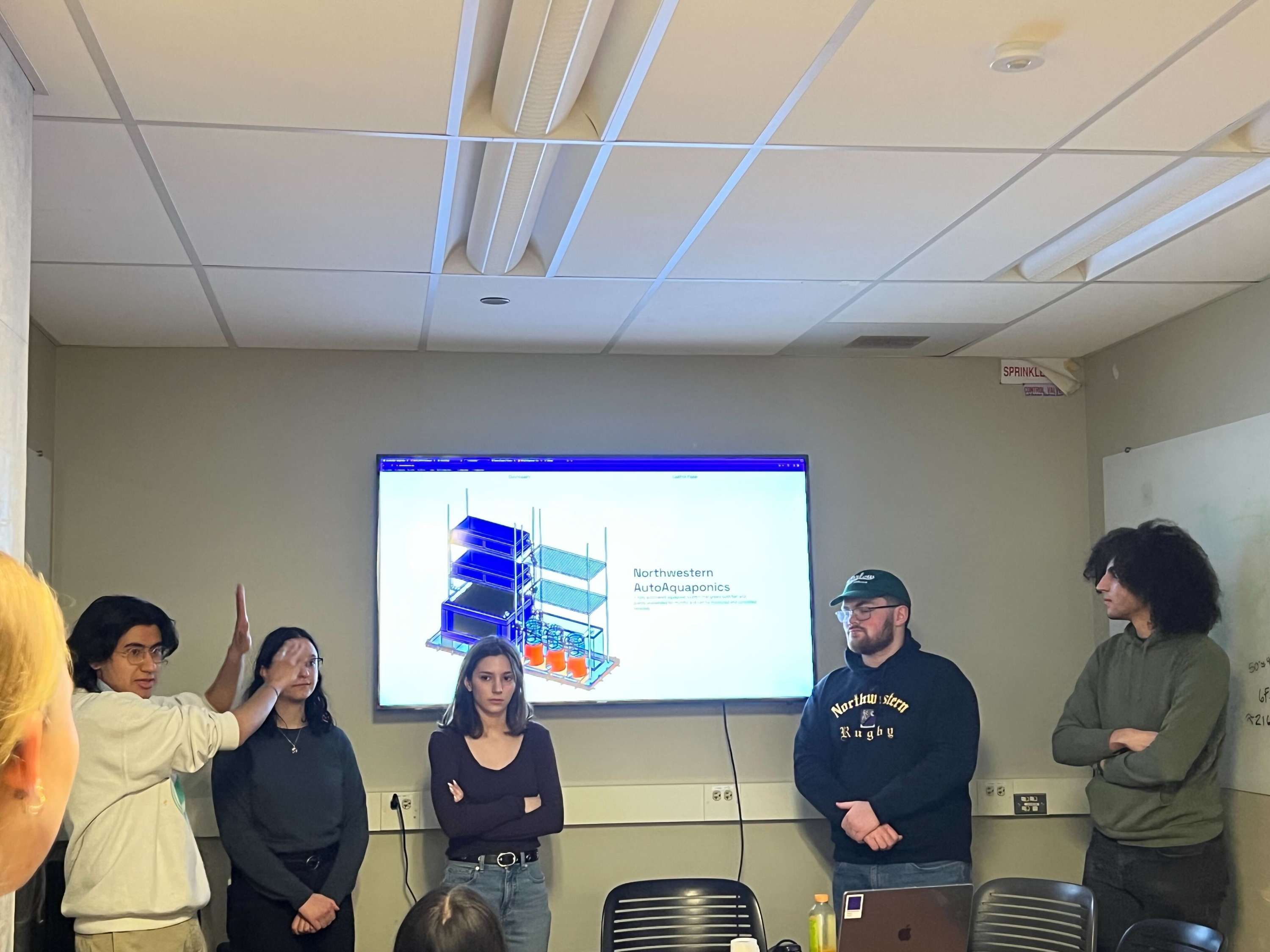

We also saw a change in leadership this quarter, with Hannah Wilks taking over as co-project manager, joining Kyan Shlipak. Like last year, we were given the opportunity to give system tours for the Society of Women Engineers’ (SWE) Career Day for Girls event! At this event, middle schoolers in the Chicagoland area are given tours of Northwestern facilities and projects to inspire them to pursue careers in STEM. AutoAquaponics is one of these projects, and we are very grateful to be a part of this exciting day! Pictured below are some highlights of the system tours and a rundown of our project (shoutout to Hannah, Jack, Eduardo, and Talia for volunteering!):

Mechanical Design

Aliza and Kyan have conducted fluid analysis calculations to create calculations for the current system, provide the necessary construction parameters for new growbeds, and ensure sufficient water flow with future additional modifications. They programmatically solved these fluid problems in IPython using the Sympy and Numpy libraries with the Engineer’s Bernoulli equation and existing standardized PVC fluid parameters. Of the six identified parameters to solve for (listed below), 1-3 are complete and Aliza and Kyan are working on the next three.

1. Velocity out of the existing upper growbed

2. Velocity out of the existing lower growbed

3. Height needed for the new upper growbed

4. Height needed for the new lower growbed

5. Expected velocity out of the new upper growbed

6. Expected velocity out of the new lower growbed

Hannah and Calvin have worked to redesign the membrane filtration system to minimize eddies through the membrane pads and ensure that all water goes through the filters. The redesign increases the size of the membrane filter tank and increases the surface area of the membrane filters to improve filtration efficiency and quality. The redesign is currently in the process of being built. All walls have been cut on a laser cutter and all materials, from pipe fits to PVC pipes to filters, have been purchased. We also 3D printed a frame to hold the filter pads in place within the system. The next stages include putting the box together, sealing it with aquarium silicone sealant, and inserting the pipe gaskets.

Hannah and Samreen have designed a shrimp cage to introduce and safeguard shrimp in the system. The CAD is done and all parts have been printed and purchased, besides the live components (moss and shrimp).

David, Lily, Samreen, Kyan, and Jonathan have completed the design and partial construction of a PVC-grow bed, which would allow us to grow many small plants with shorter roots than our larger grow beds can support. The additional plant life will both improve our crop yields and improve the water quality and nutrient cycling of the aquaponic system, We are in the process of printing grates and purchasing plants, and we are prototyping a novel part to allow us to cycle the water level in the PVC pipe between high and low levels. We are scheduling a build day to begin full prototyping and assembly.

Helena has taken over the VertiGlow project, with the aim of automatically optimizing UV radiation intensity to fit plant needs by adjusting the position of grow lights above a grow bed. She has redesigned the system using two linear actuators to adjust the height and has designed a truss system to allow the system to hold four grow lights.

Santiago and Jonathan built a cart that will allow us to move buckets of water when we need to refill the aquaponic system. It will also be utilized to move materials from the shop to our office a floor below and between the ESW office and our new storage space in Tech.

Aliza, Seeley, and Kyan designed and 3D-printed attachments to the wall of the aquarium tanks to secure and modularize the acrylic walls lining the perimeter, allowing for safe and easy removal.

Jonathan, David, Lily, Calvin, and Kyan have planned the large-scale expansion of our current aquaponic system with the construction of a larger and deeper grow bed to allow for the introduction of larger and more complex plants with deeper root systems. We have purchased a stronger shelf to support the grow bed and associated plumbing, designed the CAD for the new system, and outlined a parts list for the system. We plan to grow more complex vegetables like tomatoes and peppers within this growbed, and hope to increase complexity to strawberries for next year if the vegetables succeed

Brady, Emi, and Kyan have begun designing a semi-automated mealworm farm that generates a food source for the fish. The design has two layers with adult beetles on the top and mealworms on the bottom, separated by a metal mesh. The beetles lay eggs, which fall through the mesh and hatch. We induce pupation by isolating the mealworms and transporting the adult beetles to the top layer to repeat the cycle. We used the old compost bin to make a house for mealworms, and worms are in and living. We will check in regularly next quarter to harvest them. We are currently researching methods by which the harvesting process can be automated and fed to the fish.

Software Much progress has been made on the software team, with new features added to the website for enhanced functionality. Once the sensor box is up and running, we will now be able to export a range of data for further analysis if ever needed. Alongside exporting data, the dashboard will also display data points as they are added from the sensor box.

Aside from data visualization, Software also worked on updating user account data. We created a Google Firebase collection to store user account data, meaning that multiple users could adjust control panel settings and have potential user-specific settings in the future. To display recent control panel activity, a prototype was created to display edits in tabular form.

On the ESP32 front, software created a prototype for using object recognition to determine plant height. The groundwork was laid for more improvements in the future, since plant recognition is spotty. To boost the effectiveness of the ESP32 plant recognition, we managed to port OpenCV libraries to run on a limited ESP32 system. This means that the ESP32 will have access to a computer vision library for optimal performance.

Electronics

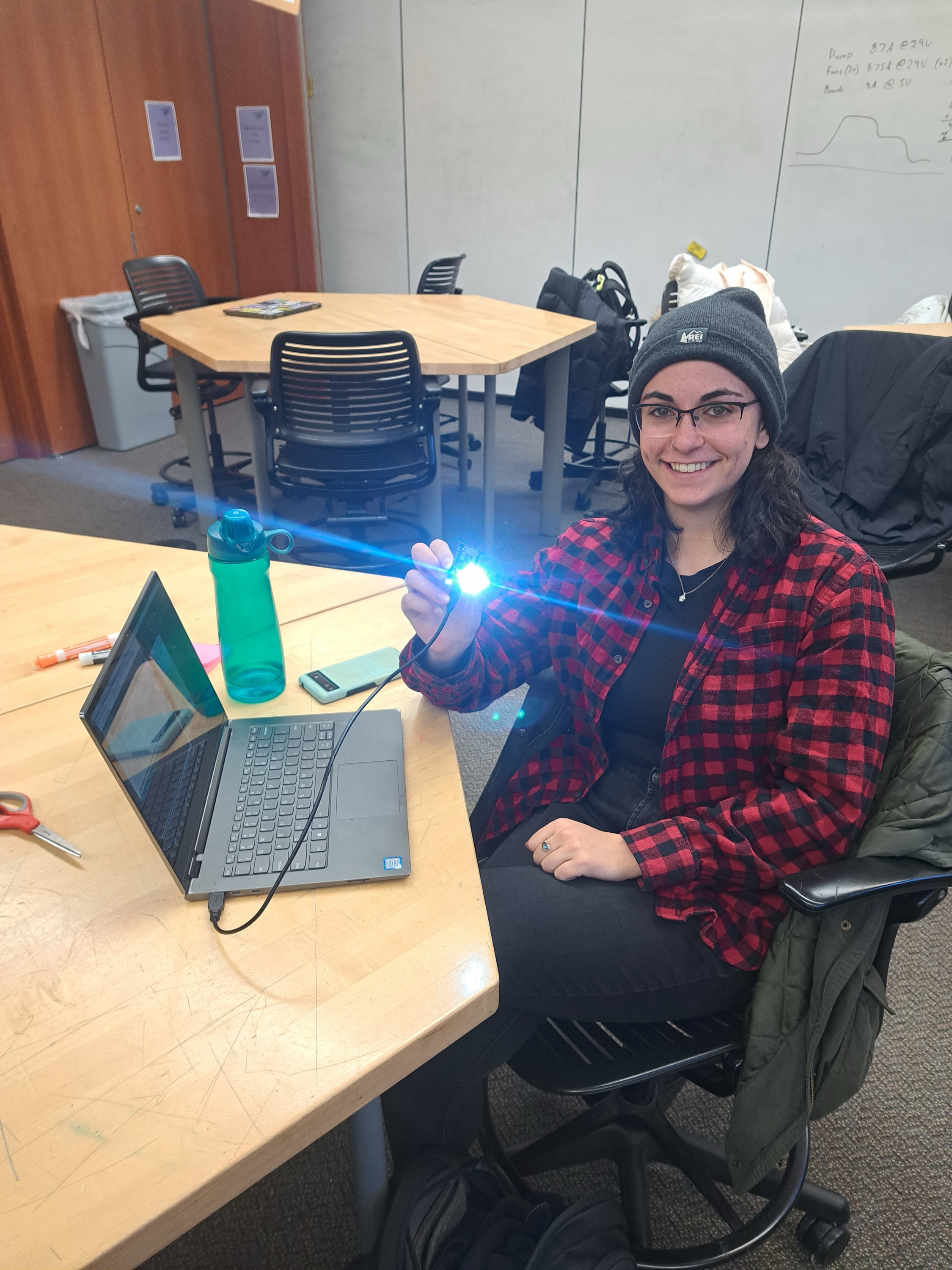

Unfortunately, our electronics team was still lacking members to complete projects. Progress was limited beyond soldering work on the sensor box. The outlet box code, which had hardcoded timers for the mechanical ball valves, was updated to have independent timers. A prototype for this code was developed by using an RTOS kernel to manage these timers, so the system is one step closer to being fully remote with soft-coded timers.

Bio

Our biological team has continued to work to ensure the maintained health of our plant and aquatic life by closely monitoring water quality and micronutrient levels.

This quarter, we had a very successful mint and kale harvest, with both flourishing in the system to an unprecedented degree. Our mint plants grew densely, completely filling half of our lower growbed and reaching the height limit. Our kale plants similarly grew to the maximum size of the lower and upper grow beds. We made fresh mint ice cream and kale salads with this quarter’s yields.

We also purchased and added some new Tetras. We quarantined them in a separate tank to ensure they wouldn’t introduce any harmful organisms or parasites into the system. Once it was safe, we added them to the aquarium, where they have lived healthily as the newest members of the AutoAquaponics system!

We are currently fixing a strange nutrient imbalance that has led to highly basic water. One of our working theories is that the decomposition of shedded snail shells has introduced additional calcium into the system. The bio and mechanical design teams are working on solutions.

Follow along to see the AutoAquaponic system and team continue to develop!

Comments