Spring 2022 Update

Spring 2022 Update

Transitioning to new leadership has led to SmartTree having a slower start to a quarter. However, both the new PMs, Fay-Ling and Thomas, quickly found their rhythm and excellent progress was made, especially on the construction side. While still trying to finish off the base pieces from last quarter, the team also started focusing on the manufacturing process of benches and top pieces.

Regarding progress toward the base pieces, the team has shifted their focus to making brackets reinforcing and connecting the side pieces. We drilled holes into the 90-degree brackets and metal sheets cut to size last quarter, countersunk them, and bent said metal sheets into 60-degree brackets.

Bending the metal sheets was especially challenging due to an oversight of high-strength galvanized steel used as stock material. It was too thick and tough for the machines available in the Prototyping Workshop at Ford Design Center. After consulting with the shop professionals, we were directed to Salomon Rodriguez, the director of the Research Workshop at Technological Institute, who aided us through the building process and granted us access to a more powerful machine that could get the job done. Here we also realized the problem of not having a clear angle to screw wood screws directly through the brackets into the base pieces, so we quickly came up with a new plan to use machine screws and acorn nuts instead.

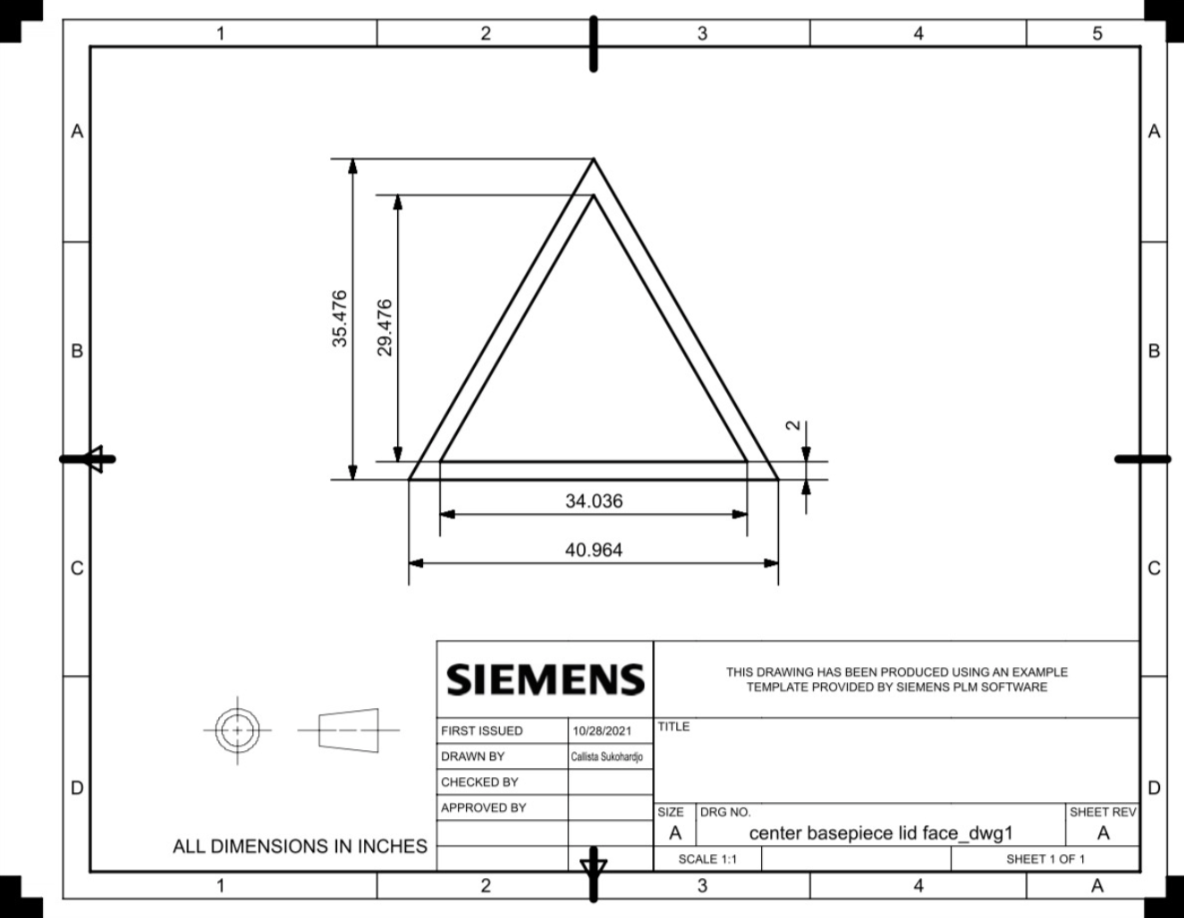

The construction team also worked on the top pieces, which are 4 simple triangular-shaped pieces with one of them having a special indent from the side to create a removable lid (see drawing below).

Due to the size and shape of the piece, we had concluded that the best way to manufacture the part was to use a router. None of the members had used it before, so we enlisted the help of formula team member Sarah Yung. Because of our inexperience, we entered the wrong measurements for the drawing fed into the machine, so the piece that was cut had incorrect dimensions. On the day that we tried again, we heard news of the miter going under maintenance for the rest of the quarter. Though unfortunate, we are still looking forward to next year when we will successfully manufacture the top pieces.

Good progress was also made on the benches. We started the quarter off by cutting rectangular wood pieces into long, thin slats using the vertical bandsaw. Then, we enlisted the help of the campus’s Concrete Canoe team with creating concrete slabs acting as support for the benches according to the mold bought. A concrete mixture was created and poured into the mold at the last meeting of the quarter. The mixture is now being cured over the summer and we are expecting to return to fully cured, sturdy concrete supports ready for decorations next fall.

In terms of electrical, progress has been slow due to the waiting for ordered parts to arrive. Furthermore, due to inexperience, there was hesitation to wire anything together with a power source for safety concerns. However, we have connected the solar panels together in parallel and tested the DC/DC converter and its capability to charge phones. The electrical team members have been tasked with doing more research on solar power over the summer and are hopeful to have major development upon return.

Overall, Fay-Ling and Thomas are both extremely satisfied with the results achieved throughout this quarter as first-time project managers. Both are excited to continue leading the team and to advance the project further throughout the next year.

Hope everyone has had a great school year and we will touch base soon!

Comments