Spring 2022 Update

Spring 2022 Update

AutoAquaponics Progress From Spring of 2022

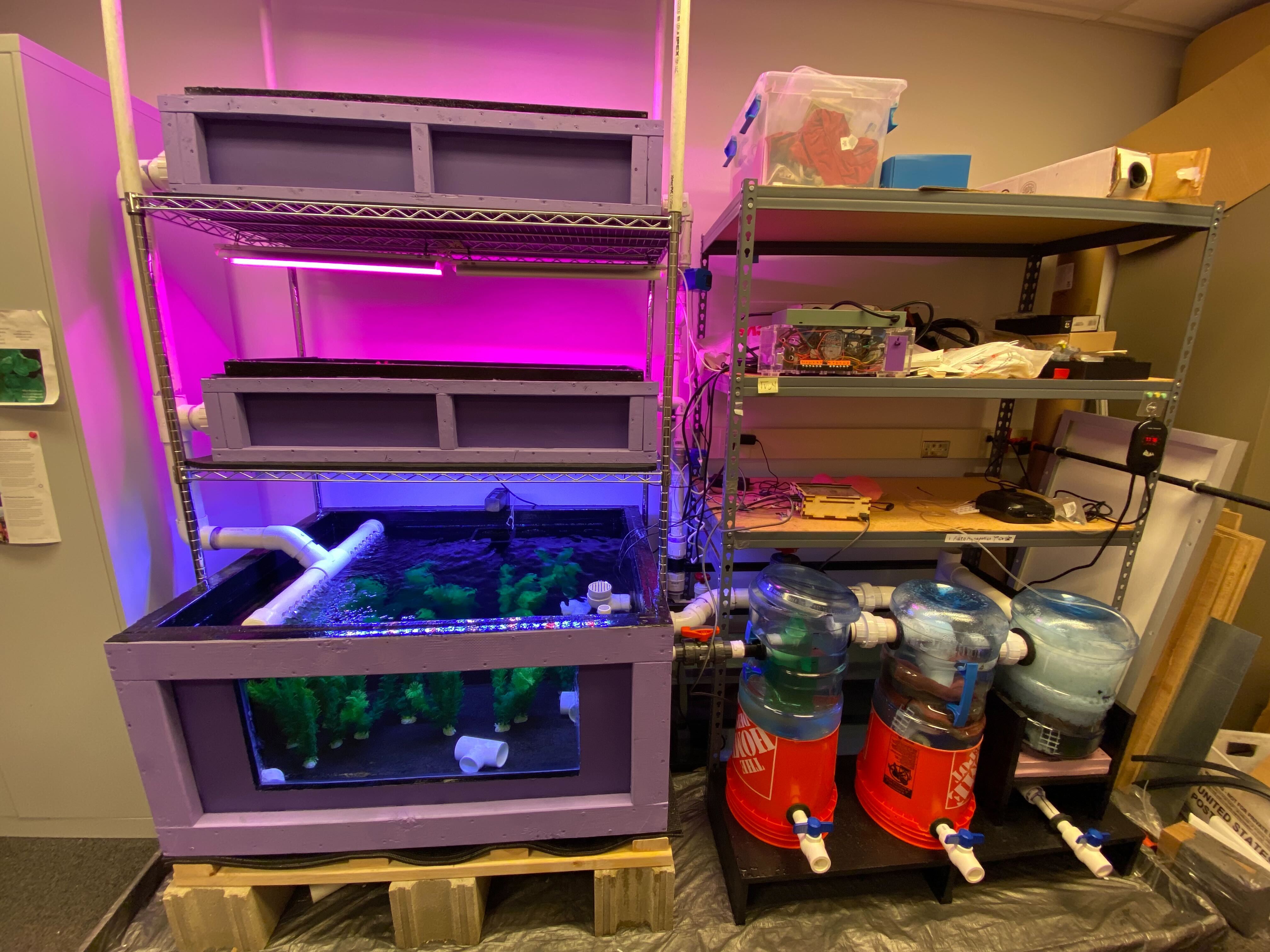

After 2 years of hard work, we are happy to announce that AutoAquaponics is officially growing fish and plants! At the same time, we welcome Alejandra Almonte, a third-year mechanical engineer, to our electronics sub-team. We are also honored to be featured in Northwestern's Earth Day special this quarter as a student group that works to build innovative technologies to improve sustainability on campus. Here's a picture of our (now operational) system as well as our fish friends:

We introduced 35 tiger barbs to our system and will likely add more to up our nitrate production:

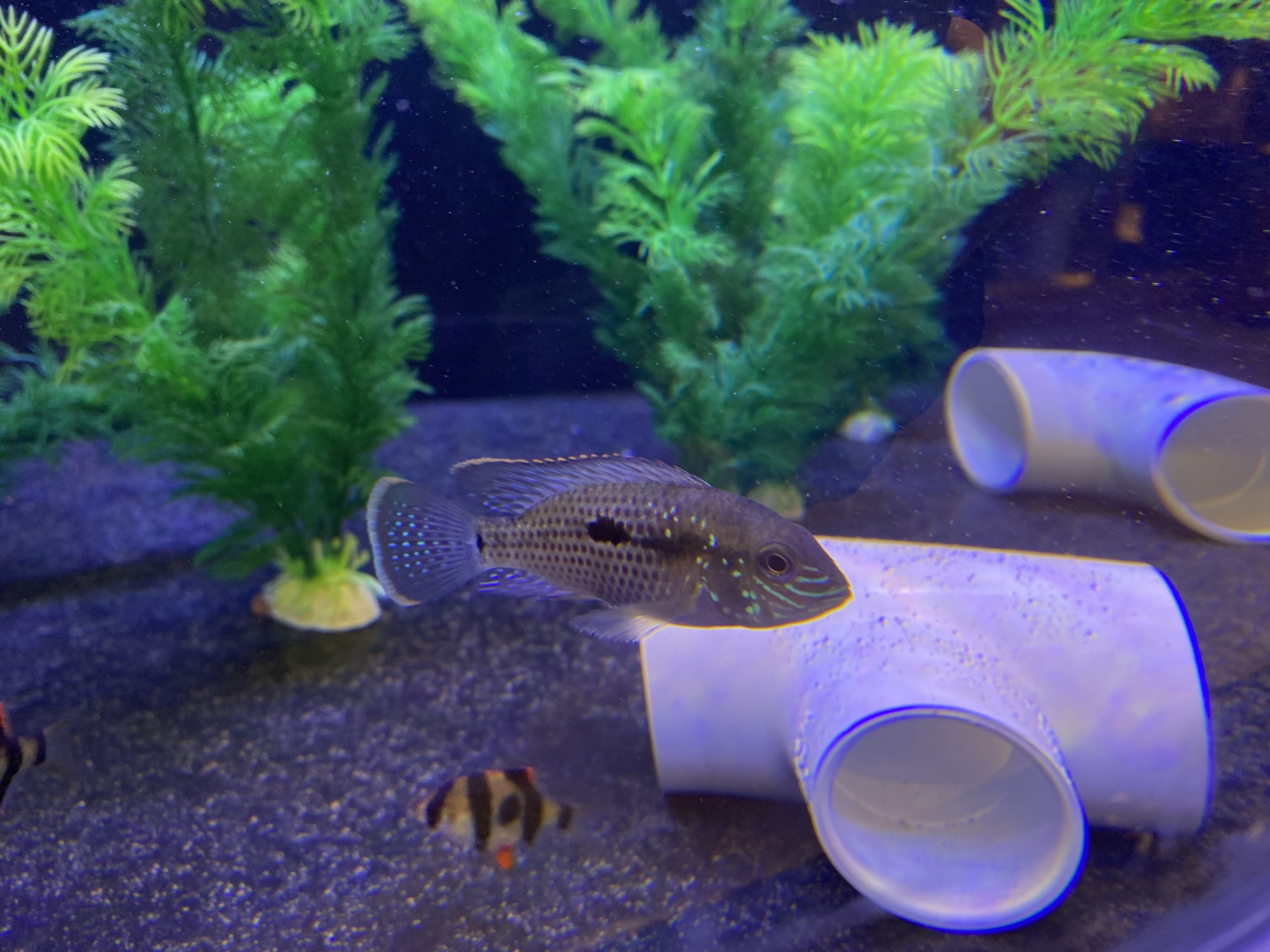

Centerpiece fish - a South American cichlid known as the green terror cichlid! Our fish is a juvenile and will grow to around 10".

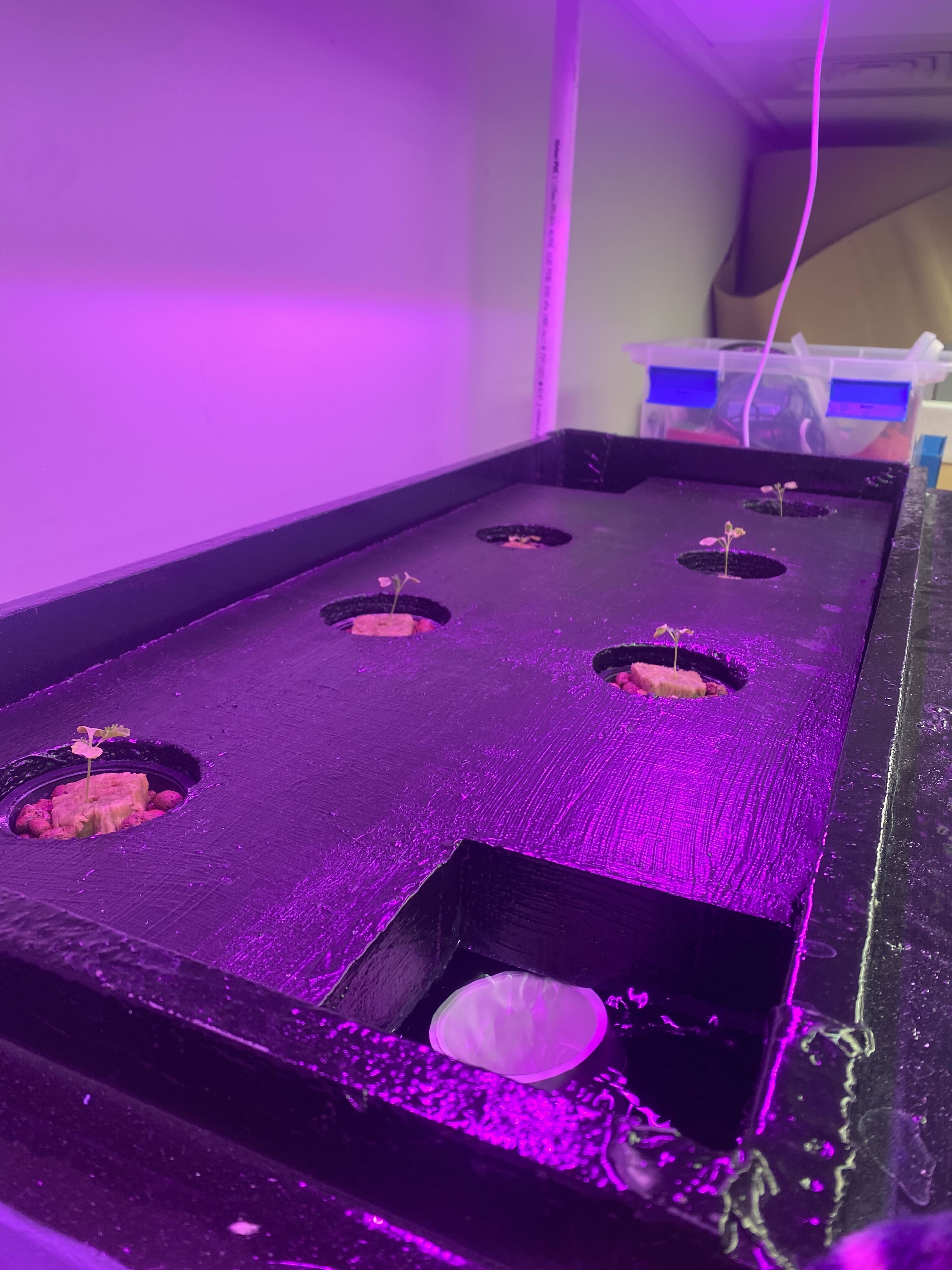

On the produce side, we planted kale on the top grow bed and basil + cilantro on the bottom:

This quarter, we completed building the floating raft necessary for our deep water culture grow bed and 3D printed various components to keep our hydrocorn growth media from entering our PVC pipes for our bottom media grow bed. Below is a top view of the system showing both our grow beds, and a closeup of what the bottom grow bed looks like before planting with our two 3D printed screens keeping our inlet and outlet pipes clear of the media.

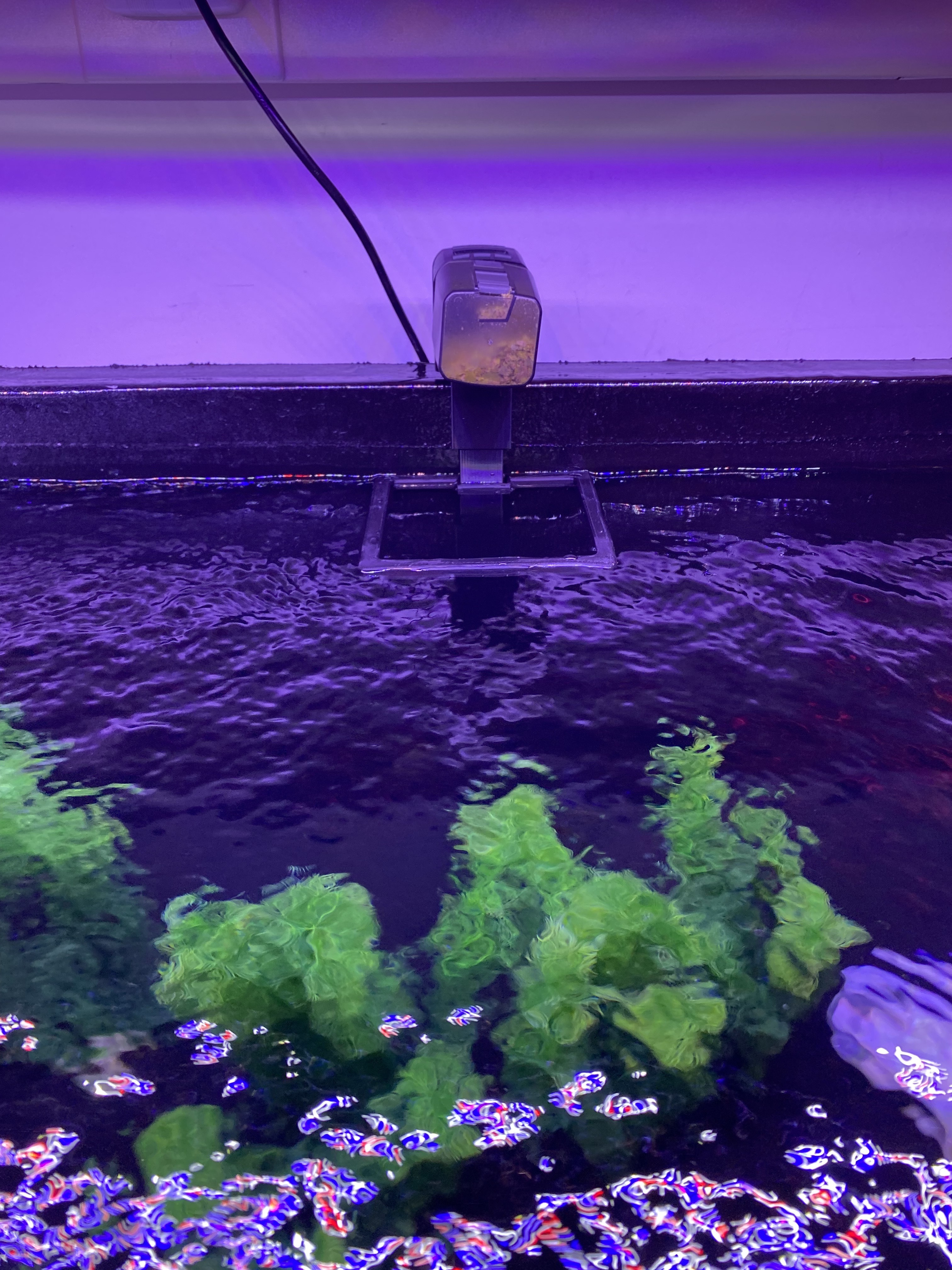

Speaking of 3D printing, our plumbing team also created a number of custom parts for our fish tank that does everything from improving our solids management to keeping fish and fish food where they are supposed to be! They made a fitting for our 1" solids lifting overflow that lets us suck water from the very bottom of the tank where fish waste sinks to. The team also designed a feeding ring that we placed under where our automatic fish feeder dispenses food so that the floating flakes wouldn't get sucked into the overflow skimmer in the tank. On top of that, a carefully designed screen on the overflow prevents our fish from making their way into the filter bottles without throttling our flow too much (can be seen in top view above). Lastly, by taking advantage of our fluid mechanics knowledge, we designed a venturi aerator for our top grow bed that can keep the deep water culture plant roots oxygenated without adding any moving components/electrical parts to the system.

Feeding ring:

Venturi aerator that injects small bubbles into the water whenever the pump forces water through it:

In addition to 3D printing, the plumbing team leveraged other rapid prototyping techniques like laser cutting to build larger screens for our biofilm reactor bottle. Earlier in the quarter, we ran into issues with our moving K1 media clogging up the reactor's drainage pipe screen as we increased flow, so we decided to cut a large screen to segregate the media to the top 2/3rd of the bottle. Since the surface area of the new screen is so big, the relative hydraulic resistance caused by the media pushing up against it became much smaller, allowing us to nearly double our flow rate without causing the tank to overflow.

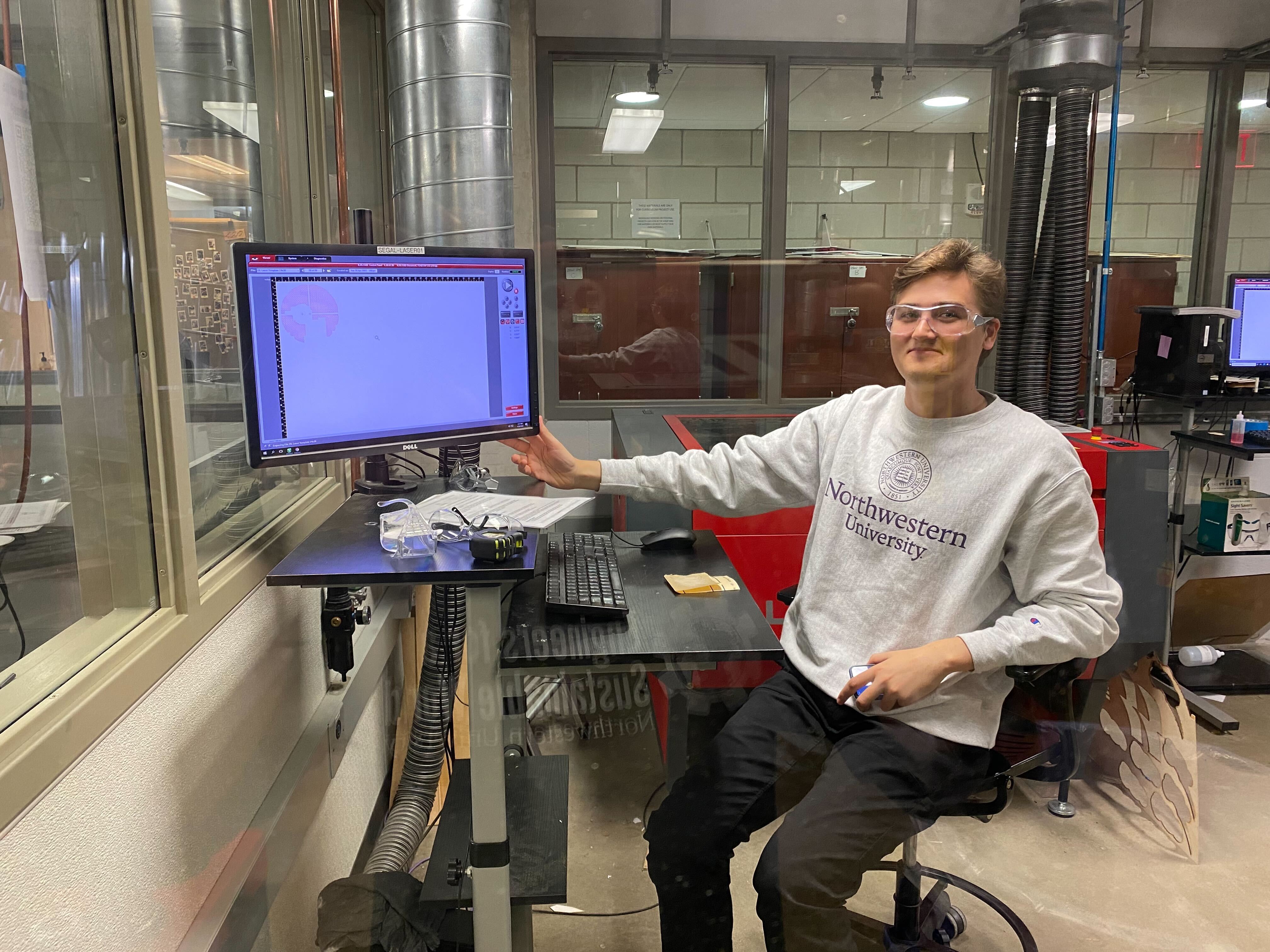

Team member operating the laser cutter to cut a large sheet of acrylic into the exact shape we need:

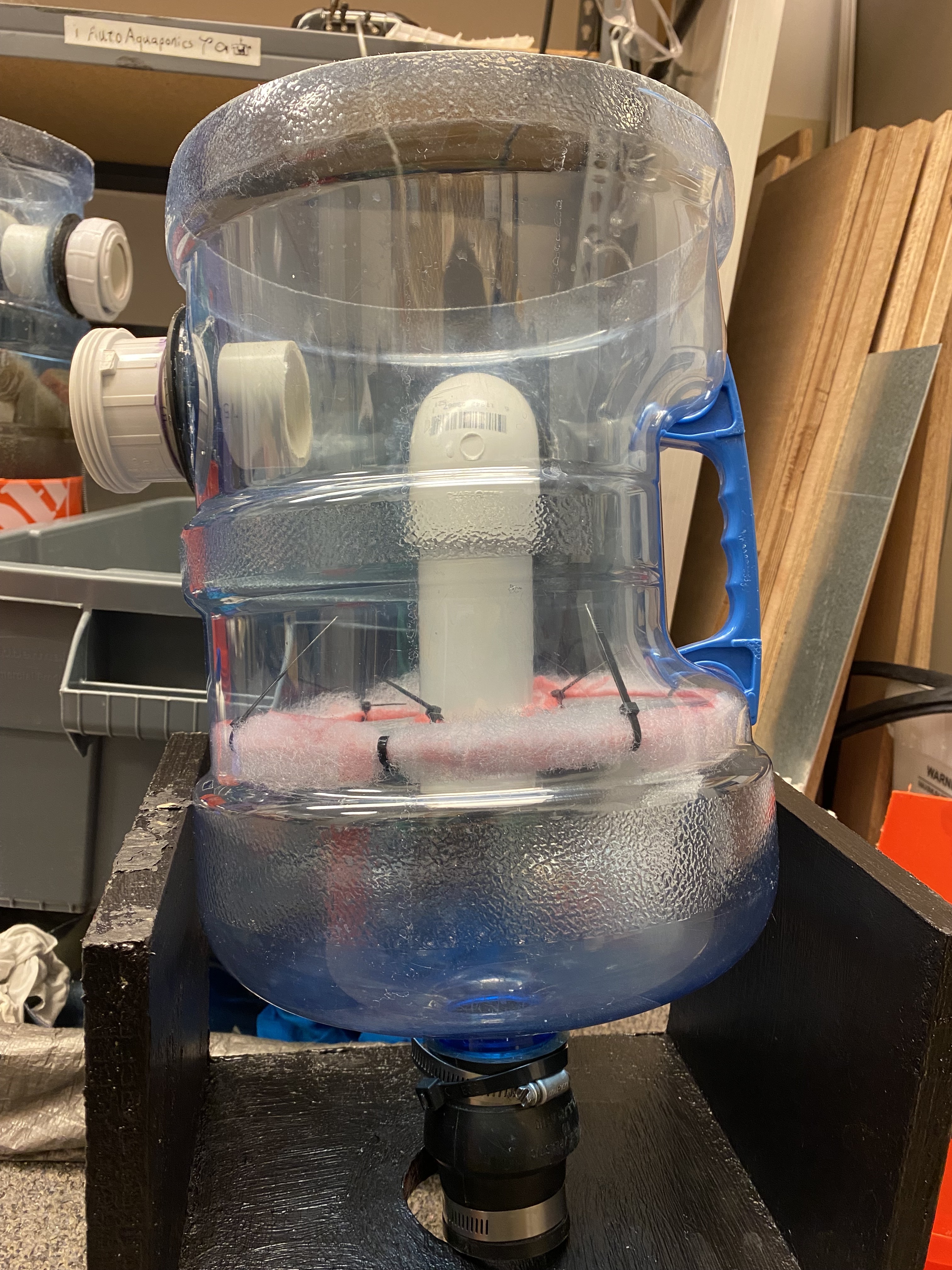

Finished product:

Screen installed with some spare filter pad to fill the gap and zip tie to put everything together:

A couple weeks into the quarter, the plumbing team also realized that the Home Depot bucket we used as the stand for the biofilm reactor tank began to crack. Despite trying to salvage it by riveting acrylic supports to it, the cracks kept on growing:

After careful assessments, we decided to scrap the bucket and build a custom stand out of wood instead. If anyone is interested in using 5 gallon water jugs as filters for aquaponics/aquaculture, this is what we recommend since the Home Depot buckets we tried earlier are much more flimsy (though they do look cooler and are less time-intensive to build).

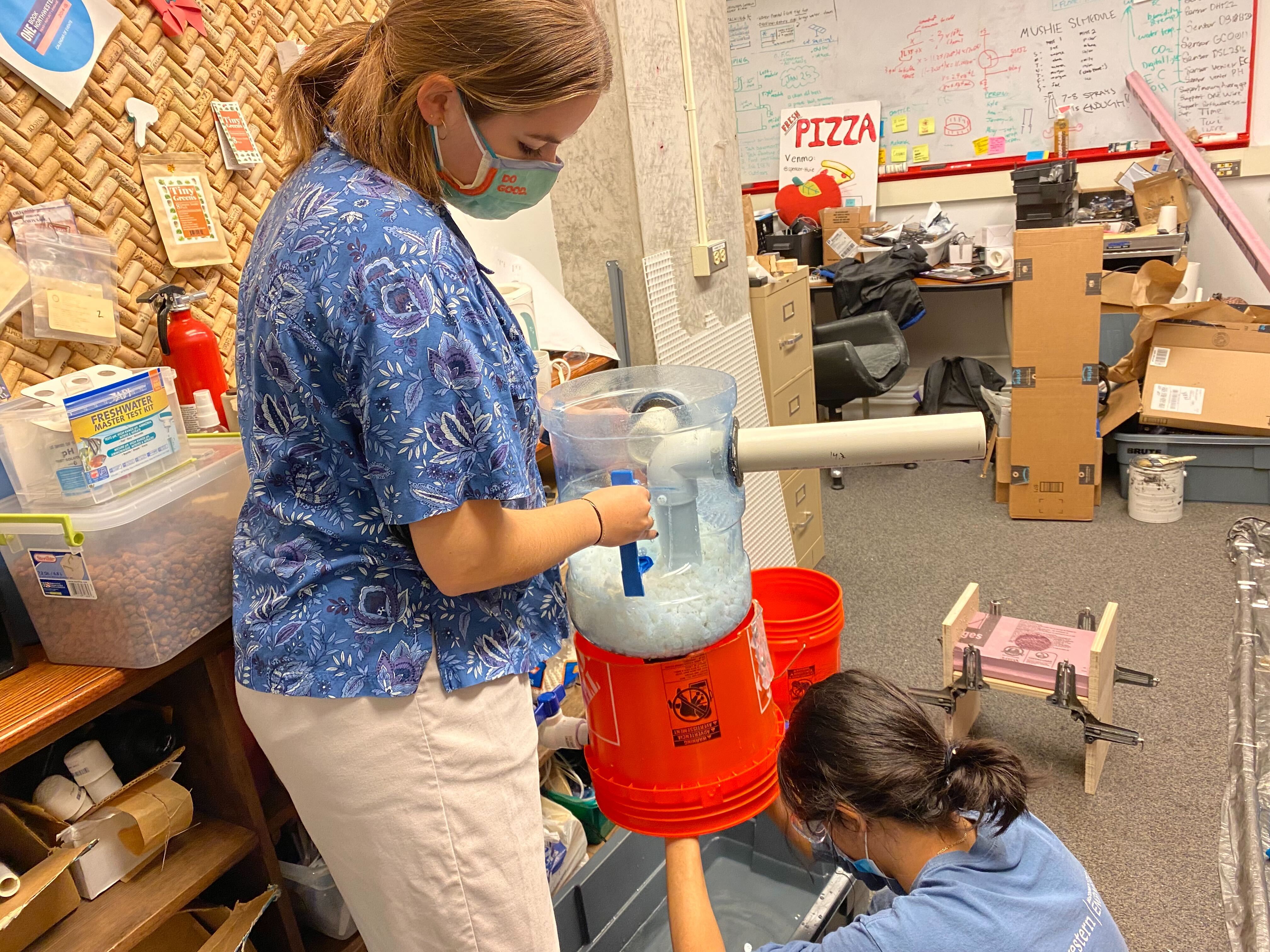

Members draining the biofilm reactor to remove the bucket stand:

Cutting wood and drilling holes for new stand!

Spot our beautiful orthographic drawing on the bottom left corner of this picture :)

Coated with more epoxy and let it cure to make the stand waterproof:

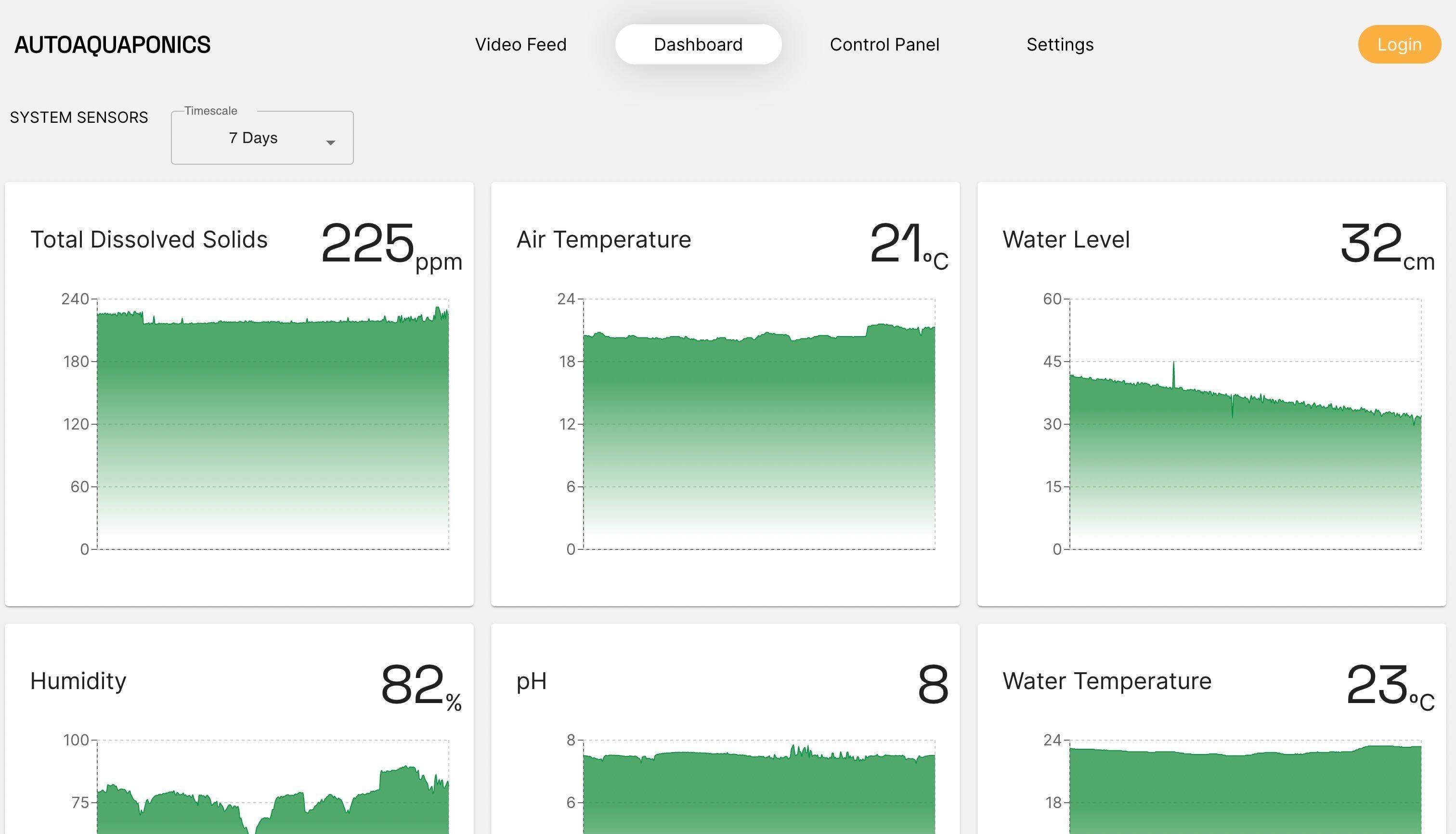

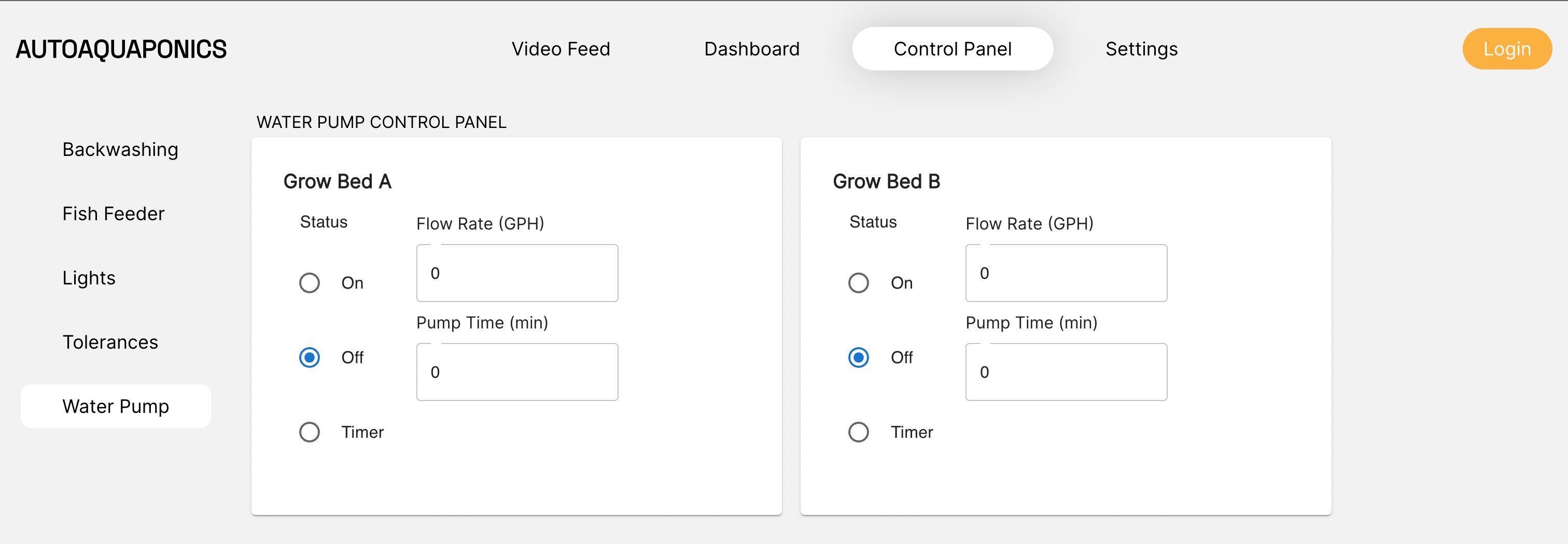

On the software and electronics side, we continued to make improvements on our control system. Right now we have our smart outlet box running numerous lights and motorized ball valves on timers to automate the flood/drain and lighting cycles. However, we currently cannot toggle these settings from our GUI, so our electronics team members are continuing to build the version of our software that will allow us to toggle our devices and adjust their timer settings through the GUI itself so that remote control can be possible. Because the front end of our Python GUI is mostly done, our software team is pivoting to creating AutoAquaponics 2.0, an exciting new version of our software that upgrades our graphical user interface from a Python application to a full-fledged website! With AutoAquaponics 2.0, anyone would be able to log onto our website with their Google accounts and check out how AutoAquaponics is doing at Northwestern by seeing our live sensor plots and live stream video. Members who have advanced access associated with their Google accounts would also be able to adjust system parameters on our website and see that change happen in real time. The biggest benefit this shift from a local Python GUI to a website has would be offloading the GUI processing task from our little Raspberry Pi to the cloud, which will drastically improve system performance. It would also allow for more flexible layouts and new exciting features, so stay tuned for more as we continue to work on this next iteration of our software!

Sneak peek to what 2.0 will look like:

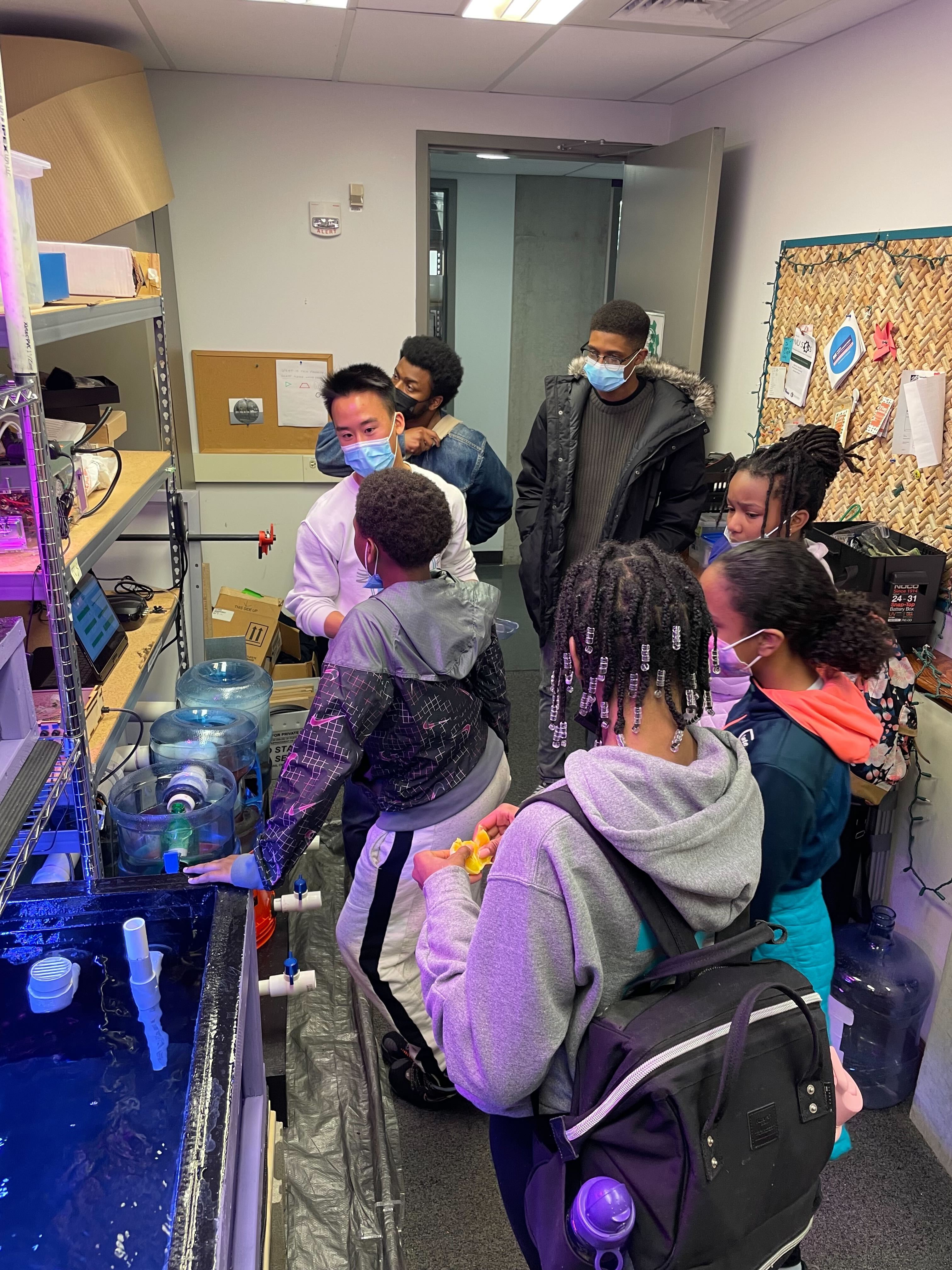

Since AutoAquaponics' ultimate goal is to become a resource for those interested in learning more about automation and aquaponics, this quarter we conducted a tour for a junior chapter of the National Society of Black Engineers and invited middle schoolers from Evanston to check out our system. It was amazing seeing their reaction to what we built together, and we thank NSBE and McCormick for this awesome opportunity!

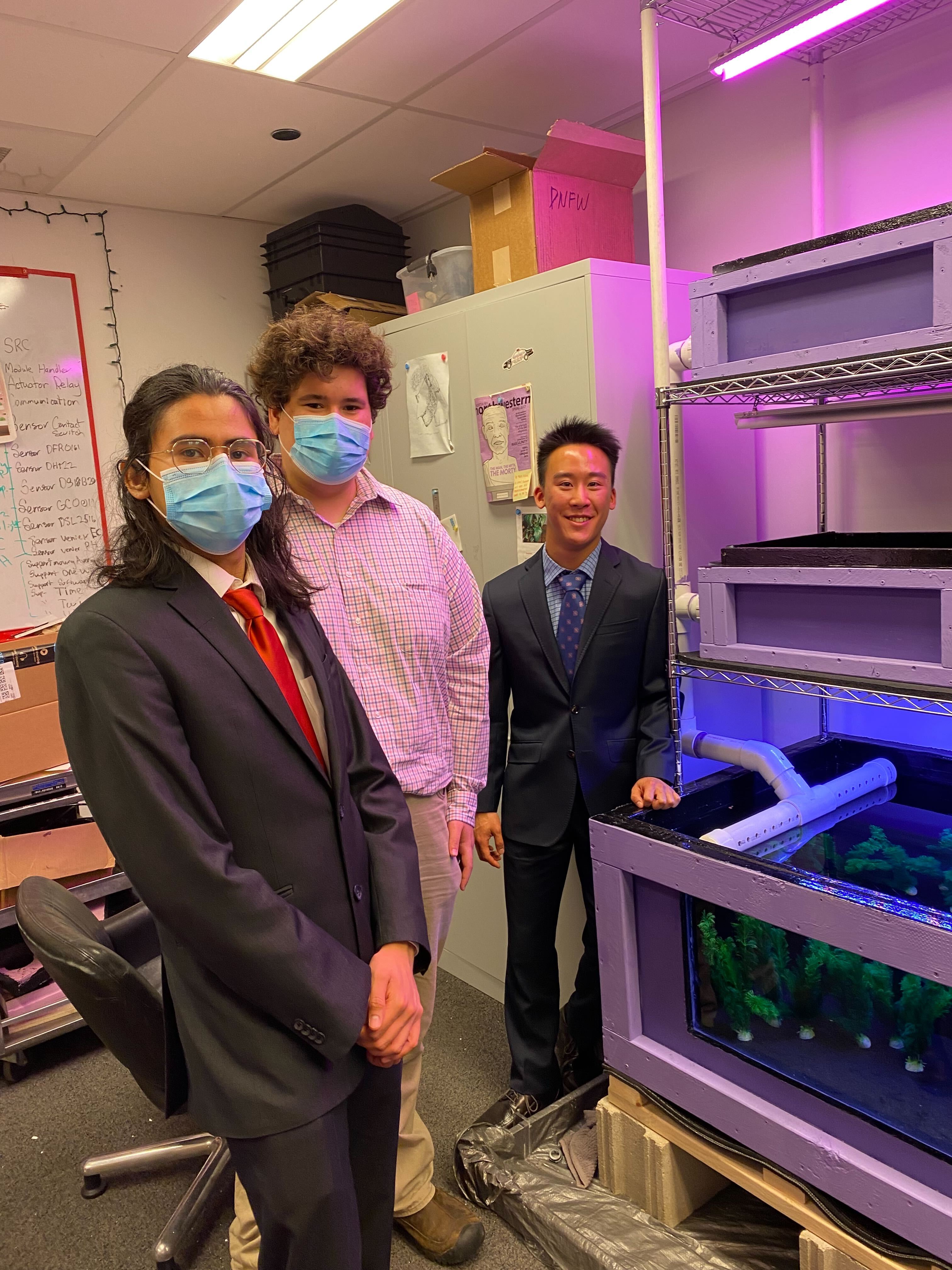

Furthermore, the one and only Dean Ottino asked three of the leaders in AutoAquaponics to present our project and how we grew from the small team we had during COVID to our present state to the McCormick Advisory Council, a group of prominent alumni who advises the dean to shape McCormick's strategy. We are beyond honored to be able to show them AutoAquaponics, and we appreciate everyone's enthusiasm on our project!

Our three presenters all dressed up:

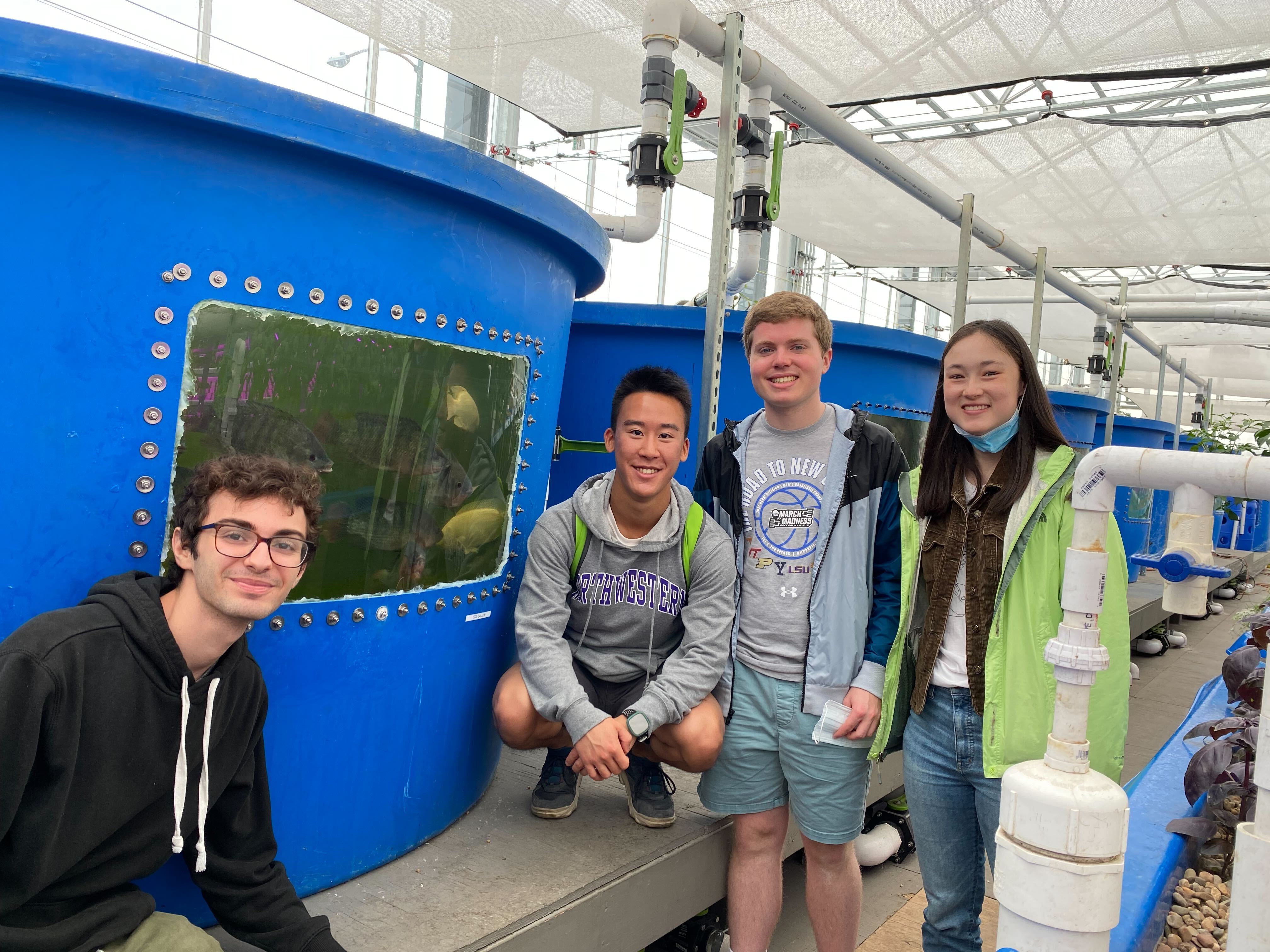

After the presentation, we received an invite from one of the board members present to visit Farm on Ogden , a nonprofit commercial scale aquaponic system in Chicago that is affiliated with the Chicago Botanic Garden. It was super cool seeing how their system works, and we got a ton of useful insight from the professionals there on the O&M of an aquaponic system and ideal plant parameters.

To further build the camaraderie on the AutoAquaponics team, we did two pizza sales to raise money for some cool ESW-AutoAquaponics hoodies for our members.

Sale 1 (slightly colder weather):

Sale 2 (we could finally be outside now!):

Hoodie design front & back (ESW logo in the front, AutoAquaponics' official logo on the back):

End of the year team photo featuring our new hoodies:

Before we wrap up this end of the year blog, we want to congratulate our friend and team member Sandra Chiu for completing her last quarter on Northwestern campus! Sandra will be studying abroad next year in Copenhagen and graduating in Spring of 2023. She has been an integral part of AutoAquaponics' development and contributed ever since our fully-remote days by designing/building our electronics box, secondary containment berm, fish tank, and grow bed. Sandra also served as the main lead for our automatic water tester sub-project, which we hope to complete next school year. Last but not least, Sandra was the aesthetics consultant of AutoAquaponics, and is responsible for not only the color layout of our fish tank/grow beds but also our official logo. We are grateful for the time Sandra spent with us, and we wish her the best in her future endeavors!

That is it from AutoAquaponics this school year. Thank you for your support as always, and keep an eye out for more from us in the Fall!

Comments