Winter 2022 Update

Winter 2022 Update

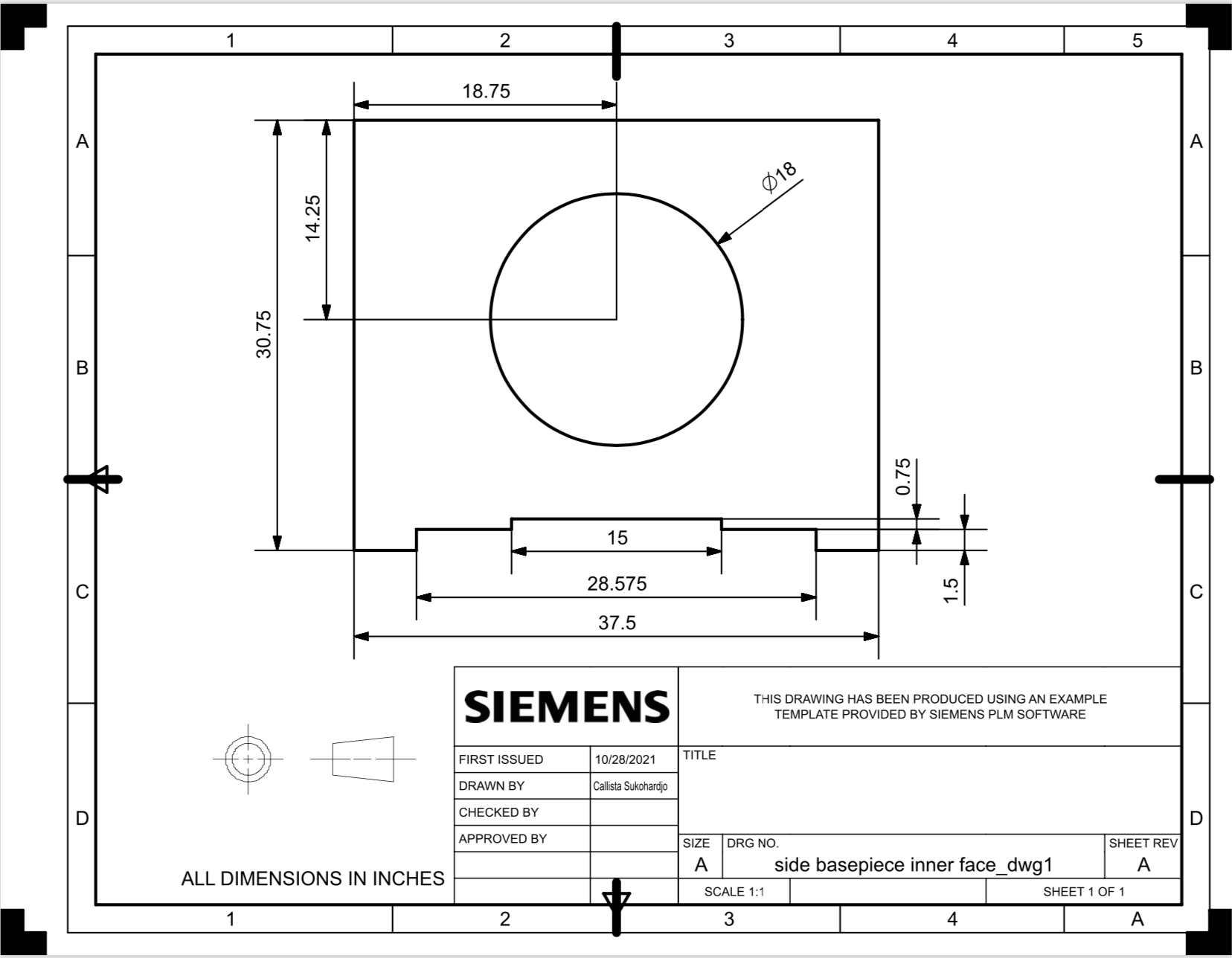

Between the first two weeks being virtual and the shop being closed off to non-DTC students at the end of the quarter, SmartTree made excellent strides in the construction and electrical groups. The construction team was only permitted 4 shop sessions, so we'd use the other weeks prior to review the construction plan and decide what needed to be done in the shop. In the shop, the team became increasingly independent, which made SmartTree PM's Cally and Katie extremely proud. Members returned to the table saw to cut the final base piece wood sheets to dimension as well as cut the bench slats using a 96" piece of wood!! Learning how to use the machine to the full capacity, members gained they'll be able to take with them to future shop builds. Additionally, all members learned how to use the jigsaw to cut out the circular shapes for wire holes as well as the complex geometries for the inner face of the base pieces (blueprint seen below).

The center hole of the circle requires a smooth finish because members may need to fit a body or an arm through the holes to fix wiring. Thus, members tried multiple methods to find the best method for sanding. At first, they tried to use a classic orbit sander, but this became hard around the edges. After consulting a shop specialist, we tried to use an oscillating spindle sander. This machine had functional issues, so then another shop specialist directed us to a small handheld belt sander which did the job very well. Now, all the wood pieces requiring the smooth finish are sanded. A video is attached below as a shared link to our drive

In our last session, members learned how to cut metal sheets and brackets. Each wooden connection requires a reinforcement in form of metal brackets. We have 90 degree angles and a metal sheet we plan on bending to a custom 60 degrees to reinforce to converging wooden base piece faces. A foot shear was used for the metal sheet, and a metal bandsaw was used for the 90 degree angles. After cutting the angles to dimension, we smoothed them with a belt sander.

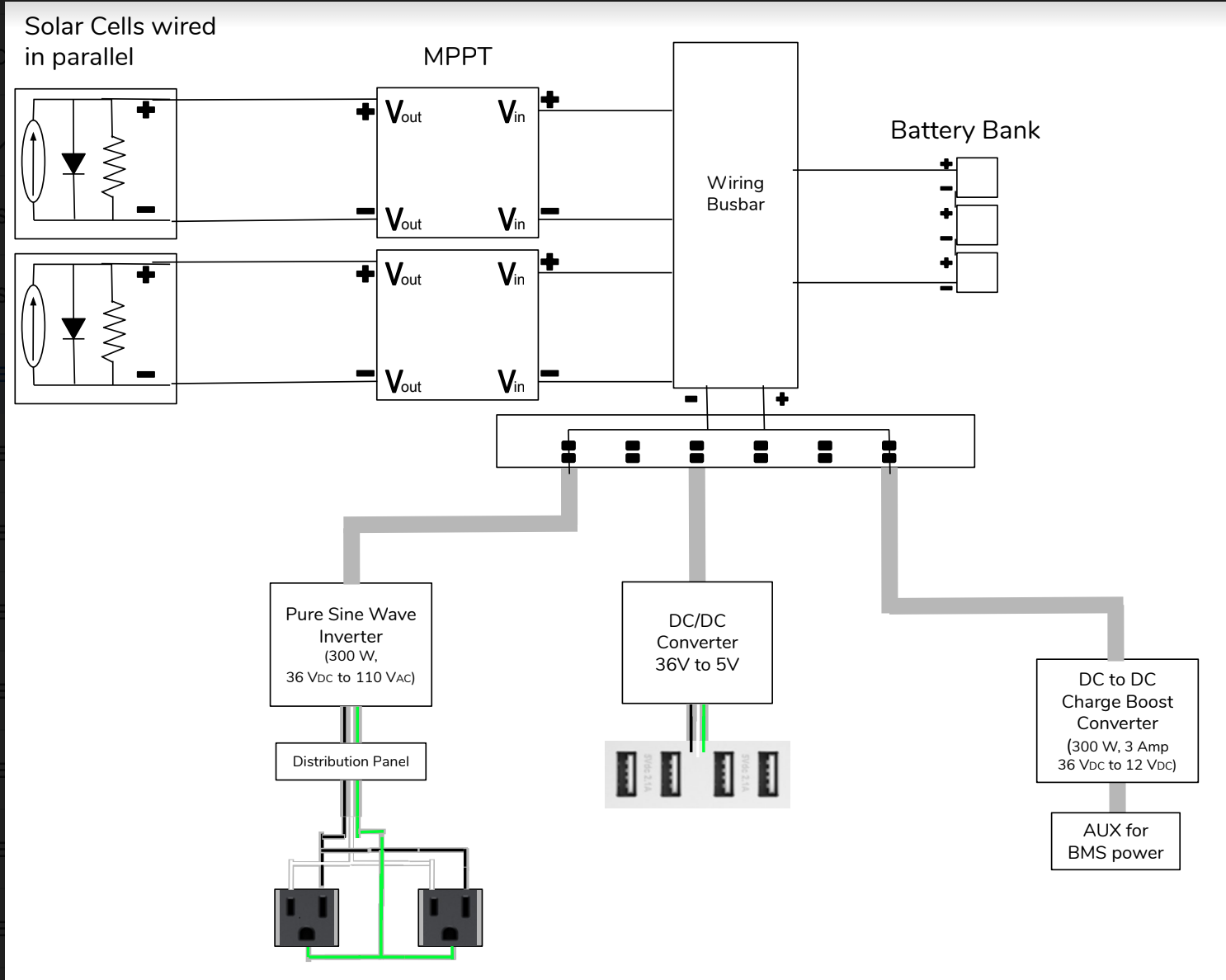

Then, there was a whole lot done for the electrical side as well. We reviewed and finalized plans with hopes to construct at the beginning of the Spring. The team reconfigured and simplified an old bill of materials that optimized cost and reliability. We are very excited for the electrical team to get the same hands-on experience as the construction team when the materials arrive.

Finally, we have appointed two new project managers. Cally and Katie are very honored to announce new PM's Fay-Ling Laures and Thomas Huang to continue SmartTrees progress! Fay-Ling (Class of '25) is a natural leader and has been part of our construction team. She takes what she is taught and runs with it, asks the necessary questions and will be starting as a shop trainer next quarter. We are excited to have her expertise spread to our entire team! Thomas (Class of '25) is another natural leader and has been one of the most committed of SmartTree upon his arrival. He's part of both construction and electrical teams, holding great knowledge in both fields. Having knowledgeable leaders in both fields will allow for more effective meetings and progress.

Cally and Katie could not have been happier with the commitment from our team, having multiple applications for the role of project manager. As time progresses, members have gained confidence and autonomy, which has leading to a more cohesive, close-knit team working together with a common goal of assembling SmartTree!

Follow the link to view a few videos recorded over this past quarter: https://drive.google.com/drive/folders/1t9Fmixj68-cB_TF6MM6yUNTZLG7yShS9?usp=sharing .

We will check back after the Spring quarter with another update on construction and electrical. Have a great Spring, everyone!

Comments